Top 10 Flow Rate Meters for Accurate Measurement and Performance Evaluation

In the realm of industrial measurement and control, the significance of accurate flow rate measurement cannot be overstated. Renowned expert in fluid dynamics, Dr. Emily Carter, has emphasized that "precise flow rate measurement is crucial for optimizing processes and ensuring system efficiency." This sentiment highlights the pivotal role that flow rate meters play in various applications, ranging from water treatment to chemical manufacturing. By accurately monitoring the flow of liquids and gases, these instruments not only support operational efficiency but also enhance safety and regulatory compliance.

As industries evolve and the demand for precision increases, the technology behind flow rate meters continues to advance. The modern flow rate meter must be capable of delivering accurate and reliable performance under varying conditions. In this context, selecting the right flow rate meter becomes an essential task for engineers and facility managers. Understanding the different types of flow meters, their unique features, and their applications is key to making informed decisions. This article seeks to explore the top 10 flow rate meters available today, providing insights into their performance and suitability for different operational needs, ensuring that every end-user can achieve optimal measurement accuracy and efficiency.

Top 10 Flow Rate Meters: Overview of Key Technologies and Types

Flow rate meters are essential instruments used in various industries to measure the volume or mass of fluids passing through a system. This measurement is critical for ensuring operational efficiency, regulatory compliance, and process optimization. There are several key technologies and types of flow rate meters, each designed to meet specific application needs and environmental conditions.

One of the primary classifications of flow rate meters includes volumetric and mass flow meters. Volumetric meters, such as positive displacement and turbine meters, measure the flow based on the volume of fluid that passes through them. In contrast, mass flow meters, including Coriolis and thermal meters, provide direct mass measurement, making them suitable for applications requiring precise mass control. Another important category is the differential pressure flow meters, which use fluid pressure drop across an obstruction to determine flow rate, commonly used in large industrial operations.

In addition to these types, advances in technology have led to the development of non-intrusive flow meters, such as ultrasonic and electromagnetic meters. These devices allow for the measurement of flow without direct contact with the fluid, minimizing the risk of contamination and wear. Understanding the differences in these technologies and their specific advantages is crucial for industries aiming to enhance accuracy and performance in fluid management processes.

Accuracy Standards: Understanding Flow Meter Calibration and Traceability

Understanding the principles of flow meter calibration and traceability is crucial for ensuring accurate measurements. Calibration is the process of adjusting a flow meter to provide readings that are accurate within a defined range. It involves comparing the meter's readings against a known standard and making necessary adjustments. Traceability, on the other hand, refers to the ability to link measurement results back to national or international standards, ensuring that the accuracy of measurements can be validated and verified.

To maintain optimal performance, it's essential to regularly calibrate flow meters. As a tip, always keep detailed records of calibration procedures and results, which can serve as documentation for compliance and performance audits. Additionally, consider the environmental factors in which the flow meter operates; temperature and pressure variations can significantly impact accuracy.

Another important aspect is to select the right calibration frequency based on the demands of your application. For critical processes, more frequent calibrations may be necessary. Remember, even high-quality metering devices can drift over time, so proactive management will help maintain their reliability and accuracy. Regular training for staff on proper handling and maintenance of flow meters is also beneficial to uphold measurement standards.

Top 10 Flow Rate Meters for Accurate Measurement and Performance Evaluation

| Flow Meter Type | Measurement Range (L/min) | Accuracy (%) | Calibration Method | Traceability | Price Range (USD) |

|---|---|---|---|---|---|

| Coriolis | 0.5 - 2500 | ±0.1 | Dynamic | ISO/IEC 17025 | 2000 - 5000 |

| Electromagnetic | 1 - 6000 | ±0.3 | Static | NIST | 1500 - 4000 |

| Ultrasonic | 0.1 - 1000 | ±1.0 | Transit-time | ISO 17025 | 1000 - 3000 |

| Vortex | 0.5 - 500 | ±0.5 | Frequency | Traceable to standards | 800 - 2000 |

| Positive Displacement | 0.1 - 300 | ±0.2 | Displacement | ISO Compliance | 500 - 1500 |

| Rotary Vane | 1 - 2000 | ±0.5 | Volume | NIST Traceable | 1000 - 2500 |

| Turbine | 1 - 5000 | ±0.25 | K-factor | Calibration Standards | 1200 - 3000 |

| Magnetic | 0.5 - 4000 | ±0.3 | Electrical | ISO 9001 | 1600 - 3600 |

| Differential Pressure | 0.1 - 1500 | ±0.5 | Pressure Drop | Traceable to NIST | 700 - 1800 |

Performance Metrics: Evaluating Flow Rate Meter Accuracy and Uncertainty

When evaluating the accuracy and performance of flow rate meters, several performance metrics should be considered. Accuracy, which refers to how close the measured value is to the true value, is paramount in any application. It is often expressed as a percentage of the full-scale reading, indicating how reliably the device can provide measurements under various conditions. Another critical aspect is the precision of the measurements, which relates to the consistency of repeated readings under the same circumstances. Instruments with high precision minimize variability and enhance the reliability of the measurements.

Another essential parameter is the uncertainty of the flow rate measurements. Uncertainty quantifies the doubt about the measurement result and can arise from various factors, including instrument limitations, environmental conditions, and operator influence. Understanding and calculating the uncertainty is vital for industries that rely on accurate flow measurements, as it informs users about the range within which the true value is likely to fall. Furthermore, the calibration of flow rate meters is crucial in maintaining their accuracy and minimizing uncertainty over time. Regular calibration against known standards ensures that instruments remain within specified tolerances, thereby enhancing measurement integrity and confidence in the data obtained.

Top 10 Flow Rate Meters: Accuracy and Performance Evaluation

Industry Applications: Selecting Flow Meters for Various Engineering Needs

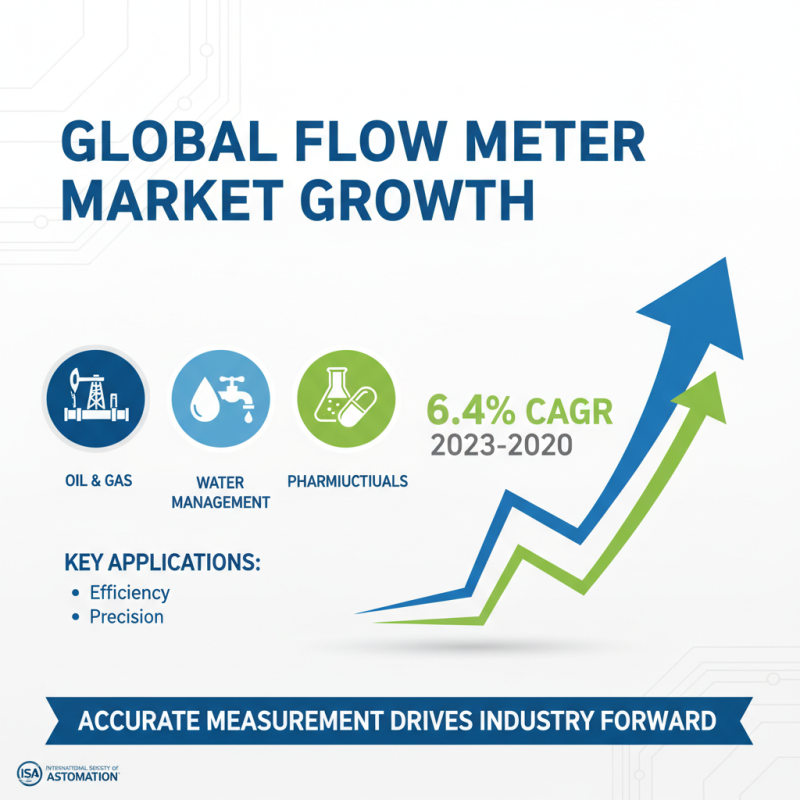

When selecting flow meters for various engineering needs, it is crucial to consider the specific applications and industry requirements. Flow meters are fundamental in industries such as oil and gas, water management, and pharmaceuticals, where precise measurement can significantly impact efficiency and compliance. According to a recent report by the International Society of Automation, the global flow meter market is projected to grow at a compound annual growth rate (CAGR) of 6.4% from 2023 to 2030, underscoring the increasing demand for accurate flow measurement technologies across multiple sectors.

Different applications necessitate various types of flow meters. For instance, in the water treatment industry, electromagnetic flow meters are favored for their ability to measure conductive liquids accurately, while in the petrochemical sector, positive displacement meters are commonly used for their reliability in measuring viscous fluids. A study by the American Society of Mechanical Engineers indicated that the wrong choice of flow meter can lead to measurement errors of up to 10%, emphasizing the need for careful selection based on fluid properties, temperature, pressure, and the specific requirements of the process involved. Engineers must also consider environmental factors and regulatory compliance when choosing flow meters, ensuring that the selected technology meets the stringent standards set forth by industry regulations.

Emerging Technologies: Innovations Shaping the Future of Flow Measurement

Emerging technologies are revolutionizing the flow measurement sector, enhancing both accuracy and efficiency in various industrial applications. Innovations such as smart sensors and IoT-enabled devices are at the forefront of this transformation, enabling real-time data collection and analysis. These advancements allow operators to monitor flow rates remotely, ensuring immediate responses to any anomalies. Furthermore, the integration of artificial intelligence algorithms enhances predictive maintenance, reducing downtime and operational costs.

Additionally, the development of advanced materials and manufacturing techniques contributes significantly to improving the durability and accuracy of flow meters. These innovations help in the creation of sensors that can withstand extreme conditions, thereby broadening their application range across industries such as oil and gas, water treatment, and pharmaceuticals. As the demand for precise and efficient flow measurement continues to grow, the ongoing research and investment in these emerging technologies promise to shape a more connected and automated future, pushing the boundaries of performance evaluation.

Related Posts

-

The Future of Flow Meters Technology Trends and Their Impact on Industrial Efficiency

-

Understanding the Importance of Water Flow Meters in Efficient Resource Management

-

How to Choose the Right Mag Meter for Your Industrial Applications

-

Unlocking Industrial Efficiency: How Advanced Flow Transmitters Improve Process Control

-

Understanding Flow Transmitters: The Key to Accurate Fluid Measurement in Industrial Applications

-

Innovative Alternatives to Inline Flow Meter Solutions for Enhanced Measurement Accuracy