Top 10 Oil Flow Meters Reviews and Buying Guide for Accurate Measurements

In the realm of industrial applications, the significance of precise measurements cannot be overstated, particularly when it comes to the oil and gas sector. An expert in the field, Dr. Emily Carter, a leading engineer and consultant specializing in fluid dynamics, emphasizes the importance of accuracy by stating, "The efficiency of any oil production or distribution system is heavily reliant on the effectiveness of its oil flow meters." This statement serves as a guiding principle for professionals who seek reliable solutions for measuring oil flow.

As businesses strive to optimize their operations, the demand for high-quality Oil Flow Meters has surged. These instruments are critical for ensuring that the right amount of oil is measured and dispensed, thus reducing waste and enhancing productivity. With various types of flow meters available on the market, understanding their functionalities, advantages, and limitations becomes essential for making informed purchasing decisions.

In this review, we will explore the top 10 oil flow meters, highlighting their features, specifications, and ideal applications. Whether you are a seasoned industry professional or a newcomer seeking guidance, our comprehensive buying guide will equip you with the knowledge needed to select the most suitable Oil Flow Meter for your specific requirements, ensuring accuracy and efficiency in all your operations.

Understanding Oil Flow Meters: Types and Their Applications

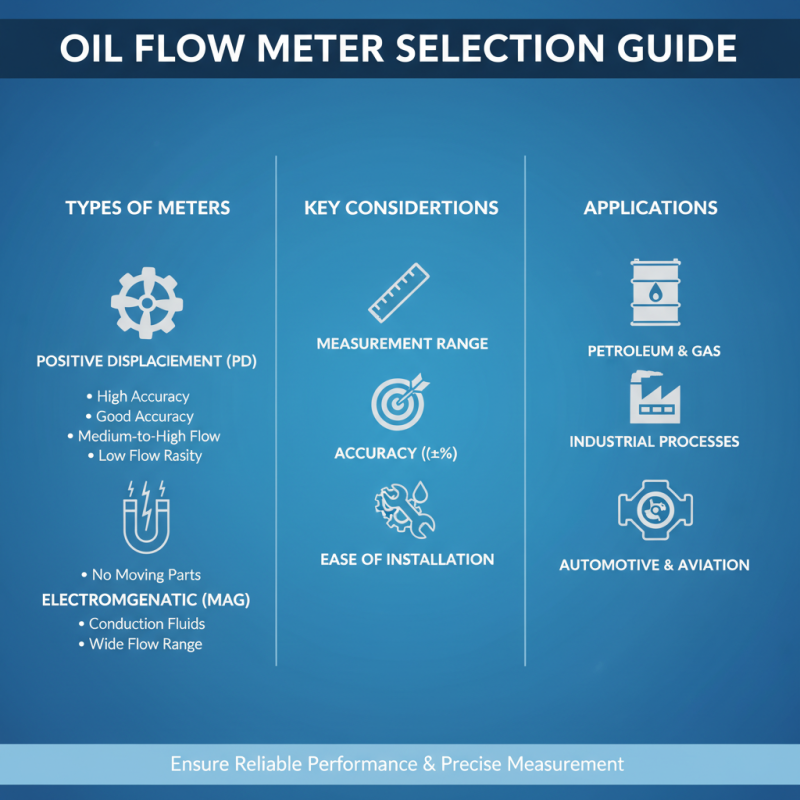

Oil flow meters are essential instruments used in various industries to measure the flow rate of oil, ensuring accurate monitoring and management of resources. There are several types of oil flow meters, each designed to meet specific needs and applications. The main categories include:

- Positive displacement meters, which work by trapping a fixed volume of oil and counting the number of times it is filled to measure flow;

- Turbine meters, where the flow of oil causes a turbine to spin, generating a measurable output;

- Ultrasonic meters, which utilize sound waves to determine flow rates without any moving parts.

The applications of oil flow meters are diverse, ranging from oil and gas production to manufacturing and transportation. In the petrochemical industry, accurate measurements of flow rates are critical for inventory management and regulatory compliance. In transportation, these meters help track the volume of oil being loaded and unloaded, enhancing operational efficiency and accuracy. Additionally, in renewable energy sectors, oil flow meters facilitate the measurement and verification of biofuels and other oils, supporting sustainable practices.

Understanding the different types of oil flow meters and their suitability for specific applications is crucial for selecting the right meter to ensure precise measurements and optimal performance.

Key Features to Consider When Selecting an Oil Flow Meter

When selecting an oil flow meter, it is crucial to consider several key features to ensure accurate measurements and optimal performance. One of the primary factors is measurement technology. Different technologies such as positive displacement, turbine, and electromagnetic meters each have their unique operating principles and applications.

According to a report by MarketsandMarkets, the global flow meter market is projected to reach USD 8.3 billion by 2025, with an increasing preference for electromagnetic flow meters due to their high accuracy and ability to measure various fluids, including oils.

Another essential feature to assess is the flow range and capacity. It's vital to choose a meter that accommodates the specific flow rates of your application, as this directly influences measurement accuracy and repeatability. Statistics from the International Society of Automation indicate that inaccurate flow measurement can lead to production losses of up to 20%. Additionally, materials and construction must be assessed, with options like stainless steel or coated materials providing enhanced durability and resistance to harsh environments, which is important for prolonging the lifespan of the meter.

Lastly, compatibility with existing systems is an important aspect to consider. A seamless integration with monitoring systems, data logging, and reporting tools can significantly enhance operational efficiency. The American Petroleum Institute reports that around 70% of oil and gas companies are moving towards advanced digital solutions that facilitate real-time data analysis. By focusing on these core features, you can ensure you select an oil flow meter that meets your operational requirements while providing reliable and precise measurements.

Top 10 Oil Flow Meters: Comprehensive Reviews and Comparisons

When selecting an oil flow meter, it is crucial to understand the various types available and their corresponding features to ensure accurate measurements. The market offers a range of flow meters, including positive displacement, turbine, and electromagnetic meters, each designed to cater to specific measurement requirements and applications. Comprehensive reviews often highlight factors such as measurement range, accuracy, ease of installation, and maintenance needs, which are essential considerations for anyone seeking reliable performance.

Comparison of oil flow meters can provide valuable insights into their operational efficiencies and suitability for different industries. Users typically focus on aspects like the flow rate capabilities, the type of oils being measured, and how environmental factors may affect performance. Additionally, the ease of integration into existing systems and the availability of technical support can greatly influence purchasing decisions. Ultimately, thorough research and comparisons will aid in selecting an oil flow meter that meets both accuracy and operational efficiency requirements, ensuring optimal performance in various applications.

How to Properly Install and Calibrate Oil Flow Meters

Proper installation and calibration of oil flow meters are crucial for ensuring accurate measurements and optimal performance. Start by selecting an appropriate installation site, ideally straight and level, to prevent turbulence and inaccuracies in readings. Ensure that all connections are secure, and the meter is properly aligned with the flow direction indicated on the device. If the meter requires it, consider incorporating isolation valves to facilitate maintenance without disrupting operation.

When calibrating your oil flow meter, follow the manufacturer's guidelines for specific procedures tailored to your model. A common practice is to perform a calibration test using a known reference volume of oil, allowing you to compare the readings of your flow meter against the actual volume. Adjustments may be necessary to account for any discrepancies and to refine the accuracy of the flow measurements.

**Tips:** Before starting the installation, double-check the environmental conditions, as temperature fluctuations can affect flow meter performance. Additionally, after installation, regularly monitor the calibration and conduct maintenance checks to ensure the longevity and functionality of your oil flow meter. This proactive approach will help avoid costly errors and maintain precision in your measurements.

Maintenance Tips for Ensuring Accurate Flow Measurement

When it comes to ensuring accurate flow measurement in oil flow meters, regular maintenance is crucial. According to industry reports, approximately 30% of flow measurement inaccuracies can be attributed to improper maintenance practices. By implementing routine checks and cleaning procedures, operators can significantly enhance measurement consistency and reliability. Regularly inspecting components such as sensors, flow tubes, and seals not only prevents costly downtime but also prolongs the lifespan of the equipment.

Implementing a comprehensive maintenance schedule is essential for optimizing performance. For instance, the American Petroleum Institute (API) suggests conducting flow meter calibrations at least once a year, depending on the operational conditions. This calibration process helps to identify deviations in measurement and allows for timely adjustments. Additionally, visual inspections should be performed quarterly to detect any signs of wear or buildup that may affect flow accuracy. By adhering to these recommendations, facilities can maintain a high level of measurement accuracy, which is vital for both operational efficiency and compliance with industry standards.

Related Posts

-

The Ultimate Guide to Understanding Flow Meters and Their Impact on Industrial Efficiency

-

5 Reasons Why the 2 Inch Flow Meter is a Game Changer for Your Industry

-

Ultimate Guide to Choosing the Best Clamp On Water Flow Meter for Your Needs

-

How to Choose the Right Mag Meter for Your Industrial Applications

-

How to Effectively Choose the Right Hydraulic Flow Meter for Your Industrial Needs

-

Exploring the Future of Oil Flow Meters at the 138th Canton Fair 2025 with Industry Insights and Trends