Top 10 Inline Flow Meters: Key Features, Benefits, and Buying Guide

The demand for accurate measurement of fluid flow in various industrial applications has led to the evolution of Inline Flow Meters, which are essential for optimizing processes and ensuring efficient operations. According to a recent market report by Technavio, the global flow meter market is expected to grow by over $1 billion from 2021 to 2025, demonstrating the increasing importance of precise flow measurement in industries such as oil and gas, water and wastewater, and food and beverage. Inline Flow Meters are particularly favored for their direct integration into pipelines, providing real-time data that assists in monitoring flow rates, ensuring compliance with industry standards, and minimizing waste.

Expertise in the field highlights the advantages of Inline Flow Meters. Dr. James Collins, a noted authority in fluid dynamics, emphasizes, "The ability to accurately measure flow within the system without the need for complex installation is a game-changer for industries looking to enhance operational efficiency." This reinforces the critical role Inline Flow Meters play in informing operational decisions and maintaining product quality across various sectors. With their ability to provide rapid and precise measurements, Inline Flow Meters not only enhance productivity but also support sustainability initiatives by reducing resource consumption. As we explore the top 10 Inline Flow Meters, this guide will illuminate their features, benefits, and crucial considerations for purchasing, catering to the needs of businesses aiming for excellence in fluid management.

Overview of Inline Flow Meters: Definition and Applications

Inline flow meters are essential instruments used to measure the flow rate of fluids in a variety of applications. These devices are particularly significant in industries such as oil and gas, water treatment, and chemical processing, where accurate flow measurement is critical for operational efficiency and compliance with regulatory standards. According to a report by MarketsandMarkets, the global flow meter market is projected to reach USD 8.5 billion by 2026, driven by the increasing demand for energy-efficient solutions and the need for precise measurement in industrial processes.

The primary function of inline flow meters is to provide real-time data on the flow of liquids or gases moving through a pipe. This data is invaluable for maintaining optimal process conditions, controlling inventory, and ensuring safety. Inline flow meters can be classified into various types, including ultrasonic, magnetic, and turbine meters, each offering distinct advantages suited to specific applications. For instance, ultrasonic flow meters are known for their non-invasive measurement capabilities, which significantly reduce the risk of contaminating the fluids being measured, making them ideal for the food and beverage industry.

According to a recent study by Research and Markets, the increasing adoption of advanced technologies such as smart sensors and IoT-enabled devices is also expected to contribute to the growth of the inline flow meter market, enhancing their functionality and application range.

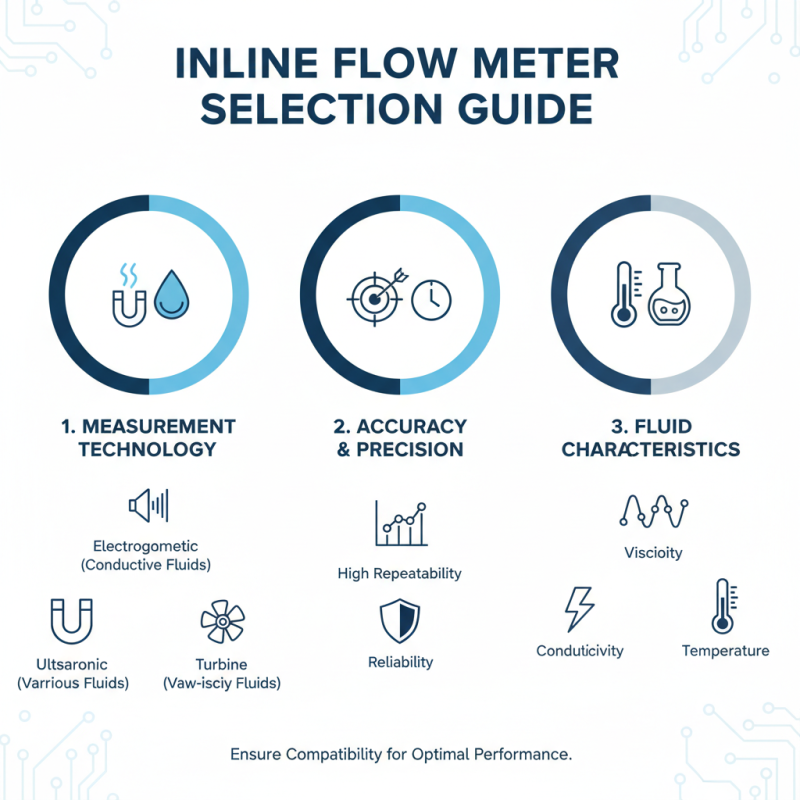

Key Features of Inline Flow Meters: What to Look For

When selecting an inline flow meter, it's essential to focus on several key features that will determine its appropriateness for your specific application. First and foremost, the type of flow measurement technology—whether electromagnetic, ultrasonic, or turbine—should align with the characteristics of the fluid being measured, such as viscosity, conductivity, and temperature. Additionally, the accuracy and precision of the flow meter are paramount; look for devices with high repeatability and reliability to ensure that your measurements are consistently correct.

Another significant feature to consider is the size and compatibility of the flow meter with your existing piping system. Proper sizing ensures that the meter will fit seamlessly into your setup without causing flow disturbances. Furthermore, evaluate the installation and maintenance requirements, as some meters may demand more complex setups or frequent calibrations. Lastly, consider the display and connectivity options, as modern inline flow meters often come equipped with digital displays and the capacity to integrate with other monitoring systems for real-time data analysis and easier management of your fluid systems.

Benefits of Using Inline Flow Meters in Various Industries

Inline flow meters have become indispensable tools across a variety of industries due to their ability to provide accurate and continuous measurement of fluid flow. One of the primary benefits of using inline flow meters is their effectiveness in enhancing operational efficiency. By delivering real-time data, these meters enable companies to monitor flow rates and detect irregularities instantaneously. This immediate feedback mechanism allows for prompt adjustments in processes, reducing waste and enhancing productivity.

Moreover, inline flow meters contribute significantly to quality control in sectors such as food and beverage, pharmaceuticals, and chemical manufacturing. By ensuring precise flow measurement, these devices help maintain product consistency and compliance with industry regulations. This level of accuracy not only helps in meeting safety standards but also minimizes the risk of costly recalls and rework, ultimately safeguarding a company’s reputation and bottom line. Additionally, their versatility allows them to be integrated seamlessly into existing systems, making them a practical choice for businesses looking to upgrade their monitoring capabilities without overhauling their processes.

Top 10 Inline Flow Meters: Key Features, Benefits, and Buying Guide

| Inline Flow Meter Type | Key Features | Benefits | Common Applications |

|---|---|---|---|

| Electromagnetic | Non-intrusive, high accuracy | Suitable for conductive fluids, robust | Water treatment, chemical processing |

| Ultrasonic | Non-invasive, wide measuring range | No moving parts, minimal maintenance | Oil & gas, HVAC applications |

| Turbine | Mechanical movement, cost-effective | Good for clean liquids, high flow rates | Food & beverage, petrochemicals |

| Vortex | Applicable for various flows, high reliability | Low maintenance, versatile application | Steam measurement, HVAC systems |

| Coriolis | Mass flow measurement, high precision | Accurate density and viscosity measurement | Pharmaceuticals, chemical industries |

| Positive Displacement | High accuracy, ideal for viscous fluids | Accurate volumetric measurement | Lubrication, chemicals |

| Rotary Piston | Robust design, accurate flow rate | Long lifespan, versatile use | Fuel measurement, oils |

| Mass Flow Meters | Direct mass measurement, high speed | Precision in varying temperatures and pressures | Food industry, chemical processing |

| Flow Switches | Simple operation, alarm function | Critical flow monitoring | Water, oils, and gas systems |

| Smart Flow Meters | Digital interfaces, data logging | Enhanced analysis and reporting capabilities | Industrial applications, remote monitoring |

Factors to Consider When Buying Inline Flow Meters

When purchasing inline flow meters, several crucial factors should be considered to ensure you select the right device for your application. First and foremost, understand the fluid properties you’ll be measuring. Different flow meters are designed to handle various fluids, including liquids, gases, and slurries. Factors such as viscosity, temperature, and pressure can significantly affect the flow meter's performance and accuracy. Make sure to choose a model that can accommodate your specific fluid characteristics.

Another important consideration is the flow measurement range. Each application has a flow rate that's optimal for its operations; therefore, it's essential to select an inline flow meter that can accurately measure within this range. Additionally, think about the installation requirements. Some flow meters may demand specific pipe sizes or configurations, impacting installation time and costs.

**Tips:** Always consult with technical specifications and seek feedback from current users before making a final decision. It can be beneficial to evaluate the maintenance requirements of different models to ensure your selected drift will not become a burden over time. Assessing the reliability and accuracy ratings of flow meters will also facilitate a more informed choice, ensuring longevity and performance in your processes.

Top 10 Inline Flow Meters: Measurement Capabilities

Top 10 Inline Flow Meters: Reviews and Comparisons

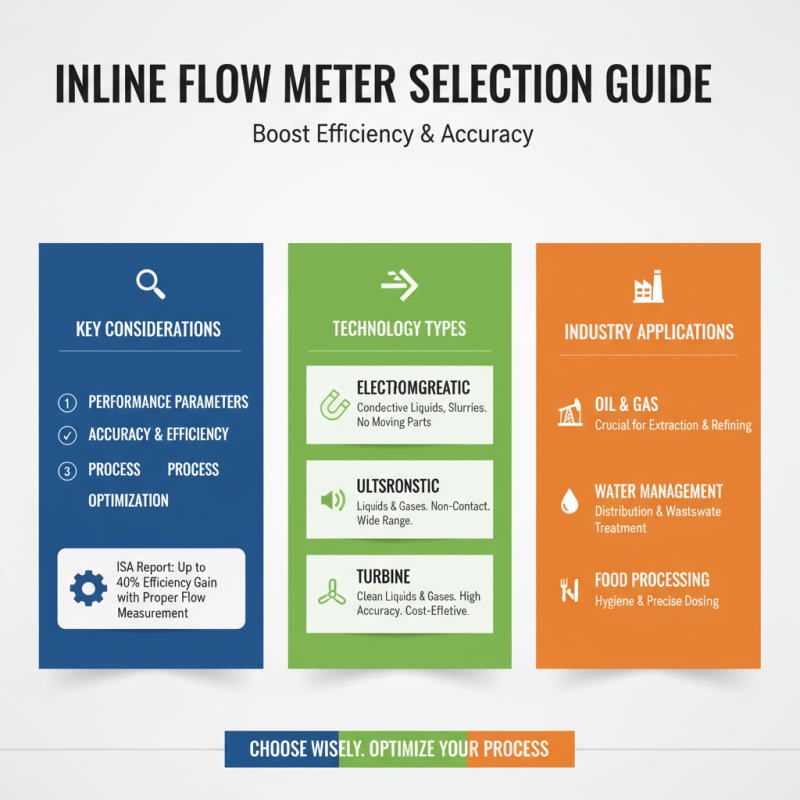

When selecting the right inline flow meter, it's essential to consider various performance parameters that can influence both accuracy and efficiency. According to a report by the International Society of Automation, proper flow measurement can enhance process efficiency by up to 40%, underscoring the significance of choosing a well-designed flow meter. Inline flow meters come equipped with diverse technologies, such as electromagnetic, ultrasonic, and turbine flow meters, each with distinct advantages suited for specific applications in industries such as oil and gas, water management, and food processing.

In terms of key features, look for aspects such as measurement range, accuracy, and installation requirements. A comprehensive review of inline flow meters often highlights their ability to handle a wide range of fluids, from clean water to viscous liquids, whilst maintaining precision measurements. For instance, ultrasonic flow meters are noted for their non-intrusive nature and ability to operate with zero pressure drop, which can be particularly beneficial in high-cost or sensitive systems. A comparative analysis reveals that electromagnetic flow meters excel in conductive liquid measurement, making them ideal for wastewater treatment facilities, whereas turbine meters are often favored for their reliability in measuring clean fluids at a lower cost. By understanding these nuances, industry professionals can make informed decisions that enhance operational performance.

Related Posts

-

Innovative Alternatives to Inline Flow Meter Solutions for Enhanced Measurement Accuracy

-

9 Proven Reasons Why Mechanical Flow Meters Are the Best Choice for Accurate Measurements

-

2025 Top 10 In Line Flow Meters: Enhance Accuracy and Efficiency

-

The Ultimate Guide to Understanding Flow Meters and Their Impact on Industrial Efficiency

-

Innovative Solutions for Inline Water Meter Efficiency Optimization

-

How to Select the Best Turbine Meter for Your Industrial Needs