Understanding the Science Behind Mass Flow Meters for Accurate Measurement

Mass flow meters are essential instruments used in various industries to accurately measure the flow rate of liquids and gases. Understanding the science behind these devices is crucial for ensuring precise measurements that can significantly impact production processes, safety, and operational efficiency. By analyzing the principles and technologies employed in mass flow meters, we can gain insights into their functionality and application in diverse fields such as chemical processing, pharmaceuticals, and food production.

The accurate measurement of mass flow is not merely a technical requirement but a fundamental aspect of quality control and resource management. Different types of mass flow meters, including Coriolis, thermal, and electromagnetic designs, utilize distinct methods to achieve their measurements. Each type has its own advantages and suitable applications, making it imperative for engineers and operators to comprehend the underlying science that governs their performance.

This exploration into the mechanisms of mass flow meters will illuminate how these instruments contribute to improved accuracy and efficiency in today’s demanding industrial environment. As we delve into the various technologies and their operational principles, we will better appreciate how mass flow meters play a vital role in maintaining high standards of measurement and facilitating advanced industrial processes.

The Fundamental Principles of Mass Flow Measurement Technology

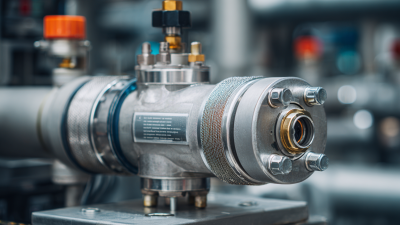

Mass flow measurement is a critical aspect of various industrial applications, particularly in sectors such as petrochemicals and pharmaceuticals. The fundamental principle behind mass flow measurement technology involves the use of Coriolis flow meters, which are recognized as the gold standard for their accuracy and reliability. These devices operate on the principle of inertia, measuring the mass flow rate of a fluid by detecting changes in the frequency of oscillation of a vibrating tube caused by the flow. Recent advancements in Coriolis technology have enhanced multi-parameter measurements, allowing for concurrent assessment of mass flow, density, and temperature—key parameters that ensure high-quality control in processes.

Mass flow measurement is a critical aspect of various industrial applications, particularly in sectors such as petrochemicals and pharmaceuticals. The fundamental principle behind mass flow measurement technology involves the use of Coriolis flow meters, which are recognized as the gold standard for their accuracy and reliability. These devices operate on the principle of inertia, measuring the mass flow rate of a fluid by detecting changes in the frequency of oscillation of a vibrating tube caused by the flow. Recent advancements in Coriolis technology have enhanced multi-parameter measurements, allowing for concurrent assessment of mass flow, density, and temperature—key parameters that ensure high-quality control in processes.

For instance, in hydrogen applications, which are rapidly gaining importance in industrial feedstock for sectors like fertilizer production, the demand for precision in flow measurement has never been higher. Coriolis meters provide accurate mass flow data essential for optimizing hydrogen production and usage, thus facilitating more efficient processes. Moreover, the emerging GranuFlow technology showcases the evolution of flow measurement by automating powder flow rate assessments, indicating a shift towards integrated solutions that maximize measurement accuracy across various materials. The ability of these cutting-edge devices to not only measure but also ensure safety and efficiency is paramount, particularly in the context of increasing demands from industries such as oil and gas, where the complexities of pipeline transportation require reliable measurement technologies.

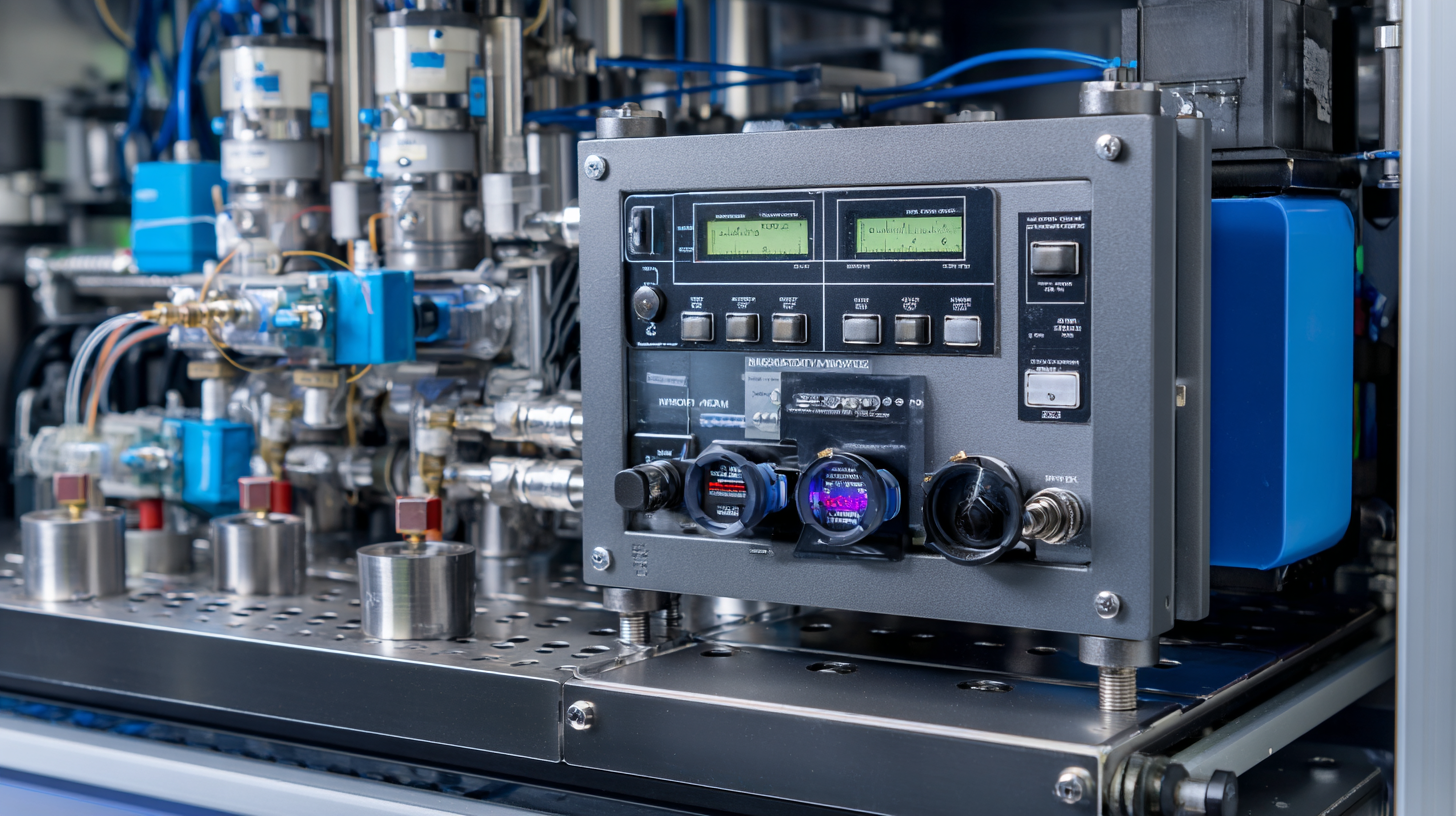

How Mass Flow Meters Function: A Deep Dive into Mechanisms

Mass flow meters are crucial instruments in various industries, providing precise measurement of fluid flow rates. At their core, they operate based on the principle of conserving mass, which means that the mass flow rate is determined by the product of fluid density and volumetric flow rate. Most commonly used types include Coriolis and thermal mass flow meters. According to a report by Markets and Markets, the mass flow meter market is projected to grow from USD 4.6 billion in 2022 to USD 6.2 billion by 2027, highlighting the increasing reliance on these devices for accurate measurements in critical applications.

Coriolis mass flow meters function by inducing vibrations in a flow tube, with the Coriolis effect causing a shift in frequency proportional to the mass flow rate of the fluid. This mechanism allows for highly accurate measurements, often within +/- 0.1% of the actual flow rate. Conversely, thermal mass flow meters rely on the heat transfer characteristics of the fluid; as the mass flow rate increases, more heat is carried away from the sensor, allowing for precise calculations of flow. According to research from the American Society of Mechanical Engineers, these meters can achieve a flow accuracy of +/- 1% under varying conditions, making them an optimal choice for industries like chemical manufacturing and food processing where minute variations can result in significant losses.

Understanding the Science Behind Mass Flow Meters - Flow Rate Comparison

This bar chart illustrates the average flow rates of various types of fluids measured using mass flow meters. Understanding these values is crucial for accurate measurements in different applications, highlighting the versatility of mass flow meters in various industries.

Factors Affecting Accuracy in Mass Flow Measurement

Mass flow measurement is a critical aspect of various industries, ensuring precise control and efficiency in processes. Several factors influence the accuracy of mass flow meters, which are essential for reliable operation. One key factor is the calibration of the flow meter, as even minor deviations can lead to significant measurement errors. Regular calibration against known standards is vital to maintain accuracy over time.

Furthermore, the installation of the flow meter plays a crucial role, as improper positioning or orientation can affect the flow profile and thus, the readings obtained.

Another critical factor is the fluid properties, including density, viscosity, and temperature. Variations in these properties can impact flow measurements, especially in complex fluids or mixtures. For instance, changes in temperature can alter the density of gases, leading to inaccurate mass flow readings. Moreover, external influences such as pressure fluctuations and vibration can introduce additional error. A comprehensive understanding of these factors is essential for optimizing mass flow measurement systems, ensuring operational integrity and product quality across various applications.

Comparative Analysis: Mass Flow Meters vs. Volumetric Flow Meters

Mass flow meters and volumetric flow meters serve critical roles in various industries, particularly in precise fluid measurement. According to recent reports, the ultrasonic flow meter market is projected to reach significant growth, driven by advancements in technology and increased applications across sectors such as water treatment, oil and gas, and food processing. These meters are classified based on type—such as segmental, insertion, and clamp-on—and by path count, including 3-path, 4-path, up to 6-path and beyond. Each configuration presents unique advantages that cater to specific operational needs, enhancing measurement accuracy and reliability.

In the context of hydrogen fueling stations, the importance of mass flow meters is underscored. As these facilities expand globally, the integration of mass flow measuring technology ensures accurate hydrogen delivery, thereby facilitating the transition to clean energy. The quality of flow measurements directly impacts operational efficiency and economic viability, making innovations in mass flow meter technology vital. Recent industry analyses highlight the increasing dependency on high-performance materials, like specialized thermoplastics, which improve measurement precision and maintain purity standards during vaccine production and other critical applications.

Understanding the Science Behind Mass Flow Meters for Accurate Measurement - Comparative Analysis: Mass Flow Meters vs. Volumetric Flow Meters

| Measurement Type | Accuracy (%) | Typical Applications | Cost ($) | Installation Complexity |

|---|---|---|---|---|

| Mass Flow Meter | ±0.5 to ±1 | Chemical Processing, Food and Beverage, Oil and Gas | 500 - 2000 | Moderate |

| Volumetric Flow Meter | ±1 to ±5 | Water Supply, HVAC, Industrial Applications | 100 - 1000 | Easy |

Applications and Industries Benefiting from Mass Flow Measurement Systems

Mass flow measurement systems are integral in various industries, providing precise data essential for efficient operations. The chemical manufacturing sector, for instance, reported a significant increase in productivity, with accurate mass flow meters contributing to a reduction in material waste by up to 15%. This precision ensures that the correct amount of raw materials is used in formulations, directly affecting profit margins and resource management.

In the food and beverage industry, mass flow meters help maintain product quality and compliance with safety regulations. According to a report from the Food Processing Industry, implementing advanced mass flow measurement technologies has resulted in a 20% improvement in compliance rates with safety standards. This not only safeguards consumer health but also enhances operational efficiency by minimizing costly recalls and ensuring consistent product output.

Additionally, the oil and gas sector has embraced mass flow measurement systems to optimize resource extraction and refining processes. Recent data indicates that companies utilizing these systems have increased operational efficiency by approximately 10%, reducing costs associated with over-extraction and maintenance. With applications ranging from pipeline monitoring to custody transfer, mass flow meters play a pivotal role in ensuring accuracy and accountability in resource management across various industries.

Related Posts

-

Unlocking Efficiency: How Air Flow Meters Enhance HVAC System Performance

-

Innovative Solutions for Magnetic Flow Meter Applications Showcased at 2025 China Import and Export Fair

-

Understanding the Importance of Water Flow Meters in Efficient Resource Management

-

Understanding the Importance of Mechanical Flow Meters in Modern Industrial Applications

-

How to Effectively Choose the Right Air Flow Meter for Your Industrial Needs

-

How to Choose the Right Non Contact Flow Meter for Accurate Measurement in Industrial Applications