Understanding the Role of Flow Transmitters in Modern Industrial Applications

In the realm of modern industrial applications, the significance of Flow Transmitters cannot be overstated. As industries continue to prioritize efficiency and precision, reports indicate that the global flow measurement market is projected to reach approximately $8 billion by 2025, reflecting a compound annual growth rate of 5.2% from 2020 to 2025. Flow Transmitters, which play a crucial role in monitoring and controlling fluid movement, are becoming increasingly indispensable across various sectors, including oil and gas, water treatment, and chemical manufacturing.

With the advent of advanced technologies, such as Smart Flow Transmitters equipped with IoT capabilities, industries are now able to enhance their operational efficiency, minimize wastage, and ensure compliance with environmental regulations. Understanding the vital role of these devices not only informs engineering and operational strategies but also catalyzes the industry’s transition towards more sustainable practices.

The Basics of Flow Transmitters: Definition and Functionality

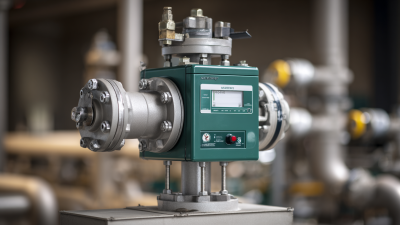

Flow transmitters are essential instruments in industrial applications, designed to measure and report the flow rate of liquids and gases within a system. At their core, these devices gather data by converting the physical flow of substances into an electrical signal that can be easily monitored and analyzed. The functionality of flow transmitters hinges on various principles, including differential pressure, electromagnetic forces, or mechanical displacement, depending on the specific type employed.

Flow transmitters are essential instruments in industrial applications, designed to measure and report the flow rate of liquids and gases within a system. At their core, these devices gather data by converting the physical flow of substances into an electrical signal that can be easily monitored and analyzed. The functionality of flow transmitters hinges on various principles, including differential pressure, electromagnetic forces, or mechanical displacement, depending on the specific type employed.

Tips: When selecting a flow transmitter, consider the type of fluid being measured. For corrosive liquids, opt for transmitters with compatible materials to prevent damage.

Additionally, maintaining accuracy is paramount; therefore, regular calibration should be part of your maintenance routine. This ensures that your flow measurements remain reliable and aid in the optimization of processes.

Flow transmitters play a crucial role in applications ranging from chemical processing to wastewater management, providing real-time data that enhances operational efficiencies and safety standards. Understanding their principles and ensuring proper installation and upkeep are vital for maximizing their benefits.

Types of Flow Transmitters: A Comparative Overview

Flow transmitters are essential instruments in various industrial applications, enabling precise measurement and control of fluid flow. There are several types of flow transmitters, each suited for different scenarios. Common types include electromagnetic, ultrasonic, differential pressure, and mass flow transmitters. According to a recent market research report from Grand View Research, the global flow transmitter market is expected to reach $5.3 billion by 2025, indicating growing demand across sectors such as oil and gas, water and wastewater treatment, and chemical processing.

Flow transmitters are essential instruments in various industrial applications, enabling precise measurement and control of fluid flow. There are several types of flow transmitters, each suited for different scenarios. Common types include electromagnetic, ultrasonic, differential pressure, and mass flow transmitters. According to a recent market research report from Grand View Research, the global flow transmitter market is expected to reach $5.3 billion by 2025, indicating growing demand across sectors such as oil and gas, water and wastewater treatment, and chemical processing.

Electromagnetic flow transmitters are widely recognized for their accuracy in measuring conductive fluids, making them ideal for applications in the water treatment industry where precision is paramount. In contrast, ultrasonic flow transmitters are favored for their non-intrusive measuring capabilities, often used in hazardous environments where safety is critical. Differential pressure transmitters, while traditional, continue to be a reliable choice due to their versatility and low cost. Lastly, mass flow transmitters, particularly Coriolis types, are gaining traction in industries requiring high precision, such as pharmaceuticals and food processing. The diversity of these technologies allows industries to select the most effective flow measurement solutions tailored to their specific operational requirements.

Applications of Flow Transmitters in Various Industries

Flow transmitters are essential instruments across various industries, facilitating the accurate measurement and management of fluid dynamics. In the oil and gas sector, for example, it is estimated that flow measurement and control account for nearly 35% of the total production costs. This underscores the significance of reliable flow transmitters in optimizing processes and enhancing operational efficiency. Advanced technologies, such as ultrasonic and electromagnetic flow meters, are increasingly being utilized to provide precise measurements under challenging conditions, ensuring that companies can monitor and control their processes effectively.

In the food and beverage industry, flow transmitters play a crucial role in ensuring product quality and compliance with safety standards. With global food safety regulations tightening, the demand for accurate measurement systems is growing. According to a recent market report, the food and beverage flow measurement market is projected to reach $1.2 billion by 2025, driven by innovations in sensor technology and the increasing need for automation. Flow transmitters not only help maintain consistency and quality in production but also aid in efficient inventory management, reducing waste and enhancing overall profitability.

Key Features and Technologies in Modern Flow Transmitters

In modern industrial applications, flow transmitters play a critical role in process optimization and efficiency. One of the key features of contemporary flow transmitters is their integration of advanced technologies such as ultrasonic and electromagnetic sensing. According to a report by MarketsandMarkets, the global flow meter market is expected to reach $8.2 billion by 2026, with ultrasonic flow meters projected to witness the highest growth rate due to their non-invasive nature and ability to measure various fluids accurately.

Another significant aspect of modern flow transmitters is their enhanced connectivity and data processing capabilities. With the rise of Industry 4.0, many flow transmitters now support IoT integration, enabling real-time data monitoring and remote access. This capability not only improves operational efficiency but also contributes to predictive maintenance strategies, reducing downtime. A Frost & Sullivan report emphasizes that companies adopting smart flow measurement technologies can increase their operational efficiency by up to 30%, highlighting the transformative impact of these modern devices in the industrial landscape.

Understanding the Role of Flow Transmitters in Modern Industrial Applications

| Feature | Description | Technology Type | Application Area |

|---|---|---|---|

| Accuracy | High precision measurement of fluid flow rates | Electromagnetic, ultrasonic | Water treatment, chemical processing |

| Temperature Resistance | Capable of operating in extreme temperature environments | Thermal mass | Oil & Gas, HVAC systems |

| Measurement Range | Wide range of flow rates accommodated | Mechanical, differential pressure | Food & Beverage, Pharmaceuticals |

| Communication Protocols | Support for modern automation communication standards | HART, Modbus, Profibus | Smart factories, Process control |

| Material Compatibility | Constructed from materials that resist corrosion and wear | Stainless steel, PTFE | Chemical manufacturing, Waste processing |

| Maintenance | Low maintenance requirements with clear diagnostics | Smart sensing, Integrated diagnostics | Industrial automation, Water supply |

Challenges and Innovations in Flow Measurement Solutions

In the realm of modern industrial applications, flow measurement solutions face numerous challenges that demand innovative approaches. Among these challenges, accuracy and reliability stand at the forefront. According to a recent report by Research and Markets, the global flow meter market is projected to reach $8.6 billion by 2025, indicating a growing need for high-performance flow measurement technologies. Industries such as oil and gas, water treatment, and chemical manufacturing require precise flow data to optimize processes, ensuring both operational efficiency and compliance with stringent regulations.

Innovations in flow measurement technologies, such as the adoption of smart transmitters and advanced digital communication protocols, are revolutionizing the landscape. These technologies facilitate real-time monitoring and data analysis, enabling predictive maintenance and reducing downtime. For instance, a study by the International Society of Automation highlighted that the introduction of smart flow meters can improve measurement accuracy by up to 50%, ultimately cutting operational costs. As industries strive for greater efficiency and sustainability, the ongoing development of flow measurement solutions that address these challenges will play a crucial role in shaping the future of industrial operations.

Flow Transmitter Technologies and Their Impact in the Industry

Related Posts

-

Understanding How Flow Transmitters Revolutionize Industrial Fluid Management

-

How to Choose the Right Inline Flow Meter for Your Industrial Applications

-

Innovative Solutions for Inline Water Meter Efficiency Optimization

-

9 Proven Reasons Why Mechanical Flow Meters Are the Best Choice for Accurate Measurements

-

How to Effectively Choose the Right Hydraulic Flow Meter for Your Industrial Needs

-

Ultimate Guide to Choosing the Best Inline Flow Meter for Your Industrial Needs