Ultimate Guide to Non Contact Flow Meter Tips for Accurate Measurements

In the realm of fluid measurement technology, the Non Contact Flow Meter has emerged as a remarkable solution for achieving accurate readings without the need for physical interaction with the fluid. This technology is particularly beneficial in industries where traditional measurement methods could lead to contamination, wear, or other adverse effects on both the equipment and the fluid itself. By employing innovative sensing techniques, Non Contact Flow Meters allow for precise flow rate measurements while minimizing the potential for damage or interference.

As industries continue to evolve and the demand for efficiency and accuracy rises, understanding the nuances of Non Contact Flow Meters becomes essential. This ultimate guide will explore various tips and best practices to ensure optimal performance and reliability in your measurements. Whether you are a seasoned professional or new to the world of flow measurement, the insights provided will help you navigate the complexities of Non Contact Flow Meter technology and harness its capabilities to enhance your operations. Through careful consideration of installation, calibration, and application, users can achieve enhanced accuracy and greater confidence in their measurement processes.

Understanding Non-Contact Flow Meters: Principles and Functionality

Non-contact flow meters are innovative devices designed to measure the flow of liquids and gases without the need for direct physical interaction with the medium. Utilizing principles such as ultrasonic, electromagnetic, and infrared technologies, these instruments provide an accurate assessment of flow rates while minimizing the wear and tear typically associated with traditional contact methods. A report by Research and Markets indicates that the global non-contact flow meter market is expected to grow at a CAGR of 6.5% over the next five years, reflecting the increasing demand for efficient flow measurement solutions across multiple industries.

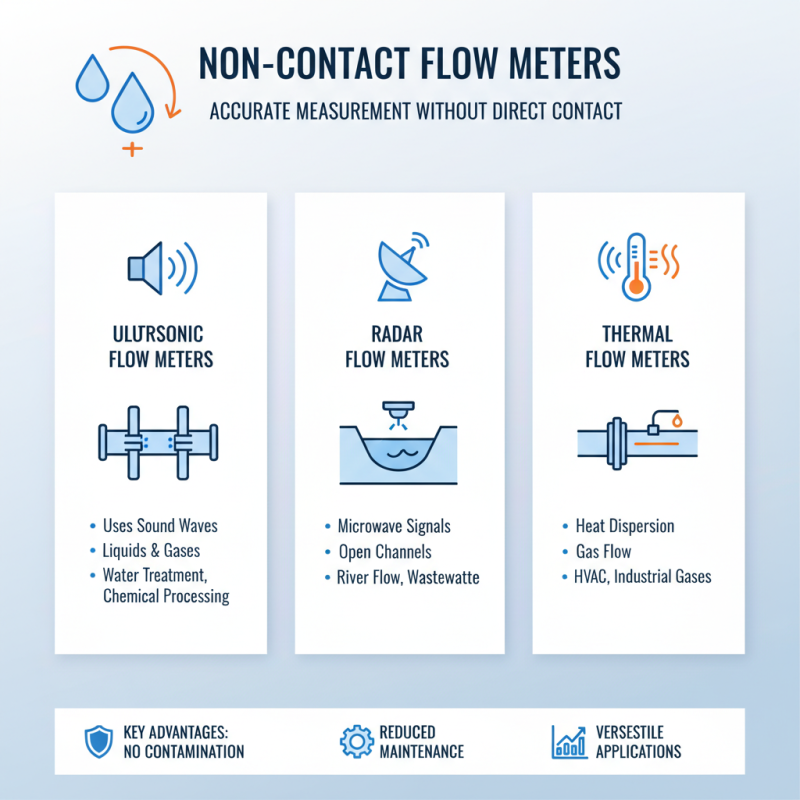

At the core of non-contact flow meter functionality lies the ability to utilize various sensing technologies tailored to different applications. For instance, ultrasonic flow meters work by emitting sound waves that travel through the fluid, measuring the time it takes for the waves to return, thereby determining the flow rate. Additionally, electromagnetic flow meters operate on Faraday's law of electromagnetic induction, effectively measuring conductivity changes in the fluid without physical contact. According to a study from the American Society of Mechanical Engineers, non-contact flow meters can achieve measurement accuracies of up to ±0.5%, making them highly reliable for critical operations in sectors such as water treatment, oil and gas, and chemical processing. By eliminating contact with the fluid, these devices also reduce risks of contamination and extend the lifespan of the measurement equipment.

Types of Non-Contact Flow Meters and Their Applications

Non-contact flow meters have become essential tools in various industries due to their ability to provide accurate measurements without direct interaction with the fluid. These meters can be broadly classified into several types, each designed for specific applications. For instance, ultrasonic flow meters use sound waves to gauge the flow of liquids or gases, making them suitable for applications in water treatment plants and chemical processing. Their ability to handle different pipe sizes and types enhances their versatility across various settings.

Another popular type of non-contact flow meter is the laser Doppler flow meter, which measures the velocity of particles within a fluid. This technology is incredibly effective in processes where high precision is required, such as in research laboratories and in the pharmaceutical industry. Additionally, there are electromagnetic flow meters, which are effective for conductive liquids, and can be used in food and beverage industries to ensure the accuracy of product flow. Each type of non-contact flow meter serves distinct needs, making them valuable to different sectors that seek to enhance efficiency and accuracy in fluid measurement.

Key Factors Influencing Measurement Accuracy in Non-Contact Flow Meters

When it comes to achieving accurate measurements with non-contact flow meters, several key factors need to be considered. First and foremost is the alignment of the flow meter with the flow stream. Proper alignment ensures that the sensors can effectively measure the flow without interference from environmental factors. Additionally, understanding the characteristics of the fluid being measured—such as its temperature, density, and viscosity—is crucial. These properties can significantly impact the accuracy of the readings, so it's essential to select a meter that is suitable for the specific fluid conditions.

To enhance measurement accuracy, one practical tip is to regularly calibrate the flow meter according to manufacturer specifications. Calibration helps in identifying any deviations in measurement precision over time and ensures that the device operates optimally. Additionally, ensuring that the area around the meter is free from obstructions can minimize disturbances caused by turbulence, which can lead to false readings. Implementing a routine maintenance schedule will also help in identifying and rectifying any potential issues before they affect measurement accuracy.

Finally, consider the environmental conditions where the meter will be installed. Factors such as temperature fluctuations, humidity levels, and exposure to chemicals can all influence the performance of non-contact flow meters. By assessing these conditions and choosing meters designed to withstand such environments, users can further enhance the reliability and accuracy of their flow measurements.

Ultimate Guide to Non Contact Flow Meter Tips for Accurate Measurements - Key Factors Influencing Measurement Accuracy in Non-Contact Flow Meters

| Measurement Factor | Description | Influence on Accuracy | Recommendation |

|---|---|---|---|

| Installation Position | The orientation and location of the flow meter. | Improper positioning can lead to turbulence and inaccuracies. | Install at a straight section of the pipe, away from bends. |

| Ambient Conditions | Temperature, humidity, and pressure surrounding the device. | Extreme conditions can distort measurements. | Ensure the device operates within specified conditions. |

| Medium Characteristics | Properties of the fluid such as density, viscosity, and temperature. | Variation in these properties can impact accuracy. | Use meters calibrated for specific mediums. |

| Calibration | Regular adjustment of the flow meter to maintain accuracy. | Neglected calibration can lead to drift in readings. | Calibrate regularly as per manufacturer guidelines. |

| Electromagnetic Interference | External electromagnetic fields impacting the sensor. | Can cause erroneous readings or fluctuations. | Install away from high voltage cables and motors. |

Best Practices for Installing Non-Contact Flow Meters

When installing non-contact flow meters, it's essential to follow best practices to ensure accurate measurements and reliable performance over time. One of the critical factors to consider is proper positioning. The meter should be installed in a straight section of the pipeline to avoid turbulence, which can lead to measurement inaccuracies. Ideally, aim for at least 10 diameters of straight piping before the meter and 5 diameters after to achieve optimal flow conditions.

Additionally, it’s vital to account for environmental factors that may impact the readings. For example, ensure that there are minimal vibrations and electronic interferences around the installation site. Protect the flow meter from direct sunlight or temperature fluctuations, which could affect sensor performance. Regular maintenance checks are also recommended to keep the device calibrated and functioning correctly.

Here are some tips to enhance installation accuracy: First, always refer to the manufacturer’s guidelines for specific installation requirements and site recommendations. Second, utilize tools such as alignment lasers to ensure precise placement of the meter relative to the flow plane. Lastly, document the setup process and any calibrations performed, as this can help troubleshoot any future issues and maintain measurement integrity. By adhering to these best practices, users can significantly enhance the reliability of non-contact flow meter measurements.

Maintenance Tips for Ensuring Long-Term Accuracy in Flow Measurements

Maintaining the accuracy of non-contact flow meters is crucial for a range of industries, as even slight deviations can lead to significant inefficiencies and financial losses. According to a report by the American Society of Mechanical Engineers (ASME), inaccurate flow measurements can result in revenue losses of up to 10% in industries like oil and gas. Consequently, implementing effective maintenance strategies becomes imperative for ensuring long-term accuracy.

One essential tip is to establish a regular calibration schedule. Regular calibration against a recognized standard can help identify any deviations in measurement before they escalate into larger issues. The Flow Measurement Council advises calibrating non-contact flow meters every six months or after significant changes in process conditions. Additionally, keeping a detailed log of calibration data can provide valuable insights into performance trends over time.

Another critical tip is to conduct routine visual inspections and cleaning. Environmental factors such as dust, dirt, and moisture can affect the sensor's performance. Establishing a cleaning protocol that aligns with the manufacturer's guidelines can extend the lifespan of the equipment and maintain measurement fidelity. As highlighted in a report by the International Society of Automation, consistent maintenance practices can improve meter performance by up to 15%, showcasing the importance of upkeep in achieving reliable flow measurements.

Related Posts

-

How to Choose the Right Non Contact Flow Meter for Accurate Measurement in Industrial Applications

-

How to Choose the Right Inline Flow Meter for Your Industrial Applications

-

5 Reasons Why the 2 Inch Flow Meter is a Game Changer for Your Industry

-

Ultimate Guide to Choosing the Best Clamp On Water Flow Meter for Your Needs

-

How to Choose the Right Mag Meter for Your Industrial Applications

-

How to Select the Right Mechanical Flow Meter for Your Industrial Needs