Understanding the Mechanisms Behind Turbine Flow Meters

Turbine Flow Meters have become an essential tool in various industries, including oil and gas, water treatment, and chemical processing, due to their high accuracy and reliability in measuring fluid flow. According to a recent industry report by MarketsandMarkets, the global flow meter market is expected to grow from $5.8 billion in 2020 to $8.2 billion by 2025, with turbine flow meters playing a significant role in this expansion. Their operational principle relies on the mechanical rotation of a turbine within the flow stream, which correlates directly with flow rates. Understanding the mechanisms behind turbine flow meters not only enhances their application in various sectors but also aids in optimizing performance and maintenance practices. As industries strive for efficiency and precision in measurement, a deeper insight into the functionality and advantages of turbine flow meters is crucial for leveraging their full potential.

Turbine Flow Meters have become an essential tool in various industries, including oil and gas, water treatment, and chemical processing, due to their high accuracy and reliability in measuring fluid flow. According to a recent industry report by MarketsandMarkets, the global flow meter market is expected to grow from $5.8 billion in 2020 to $8.2 billion by 2025, with turbine flow meters playing a significant role in this expansion. Their operational principle relies on the mechanical rotation of a turbine within the flow stream, which correlates directly with flow rates. Understanding the mechanisms behind turbine flow meters not only enhances their application in various sectors but also aids in optimizing performance and maintenance practices. As industries strive for efficiency and precision in measurement, a deeper insight into the functionality and advantages of turbine flow meters is crucial for leveraging their full potential.

Key Components of Turbine Flow Meters and Their Functions

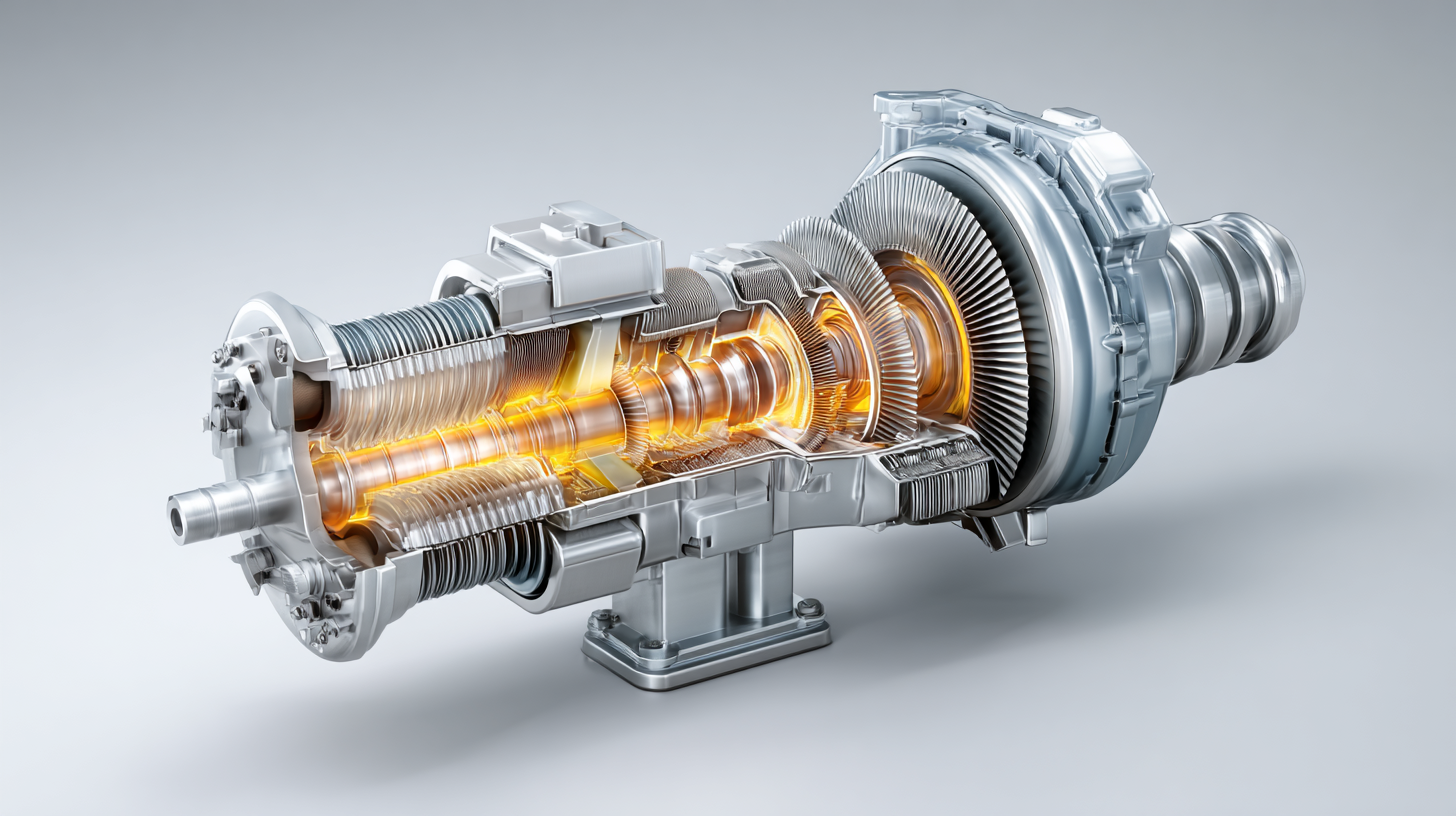

Turbine flow meters are essential instruments in various industries, providing accurate flow measurement for liquids and gases. The key components of turbine flow meters play a crucial role in their functionality and precision. At the heart of the system lies the turbine rotor, which spins as fluid passes through. The rotational speed of the turbine is directly proportional to the flow rate, allowing for real-time monitoring and data acquisition. According to a report from the International Society of Automation, turbine flow meters can achieve an accuracy of ±0.5% to ±1% of full scale, making them suitable for applications where accurate flow measurement is critical.

Another vital component is the electronic sensor, which detects the rotation of the turbine blades. This sensor converts mechanical motion into electrical signals, providing data that can be displayed, recorded, or transmitted for further analysis. In 2022, a study published by the American Institute of Chemical Engineers indicated that advancements in sensor technology, such as the use of Hall effect sensors, have significantly improved the response time and reliability of turbine flow meters. Additionally, the meter housing is designed to withstand varying pressures and temperatures, ensuring operational efficiency across different environments. Proper understanding of these components and their functions is essential to maximizing the performance of turbine flow meters in diverse industrial applications.

Understanding the Key Components of Turbine Flow Meters

The Principles of Flow Measurement in Turbine Flow Meters

Turbine flow meters operate on a straightforward yet effective principle of flow measurement. At the core of their functionality lies a rotating turbine wheel, positioned in the fluid path. As the fluid flows through the meter, it imparts kinetic energy to the turbine, causing it to spin. The rotational speed of the turbine is directly proportional to the flow rate of the fluid, allowing for precise measurements. According to a report by the Flow Measurement and Instrumentation Association, turbine meters can achieve accuracies within ±0.5% of reading, making them a reliable choice for many industrial applications.

The mechanics behind turbine flow measurement also involve the use of advanced signal processing technologies. Modern turbine flow meters often integrate electronic components that convert mechanical motion into electronic signals. This enhances the measurement accuracy and provides real-time data retrieval, essential for applications in sectors like oil and gas, chemical processing, and water management. Research indicates that with the integration of digital technology, the efficiency and reliability of turbine flow meters can exceed previous standards by over 20%, ensuring that industries maintain optimal operations while minimizing resource wastage.

Understanding Flow Patterns and Their Impact on Accuracy

Understanding the flow patterns within turbine flow meters is essential for ensuring measurement accuracy. According to a report by the American Society of Mechanical Engineers (ASME), improper flow conditions can lead to measurement errors of up to 10%. Turbine flow meters rely on the rotational motion of blades within a fluid stream, and variations in flow patterns—such as turbulence, velocity profiles, and fluid viscosity—can significantly impact their performance. To achieve optimal accuracy, it is crucial to install these meters in a manner that minimizes disturbances before the flow enters the meter.

Tips for ensuring accurate measurements include maintaining straight pipe runs before the meter, as recommended by the International Organization for Standardization (ISO). At least 10 pipe diameters of straight run upstream is ideal for reducing turbulence. Additionally, the calibration of turbine flow meters should be regularly conducted, with ASME suggesting a recalibration frequency based on usage intensity and the nature of the fluids being measured. Consistent monitoring of flow conditions can also enhance the reliability of the measurements, ultimately leading to better operational efficiency.

Common Applications of Turbine Flow Meters in Various Industries

Turbine flow meters are widely utilized across various industries due to their reliability and precise measurement capabilities. In sectors like chemical, oil, and gas, these meters offer low installation costs and exceptional performance, making them a preferred choice for downstream flow measurement challenges. Their efficiency enables industries to maintain accurate data that is crucial for operational efficiency and regulatory compliance.

In the food and beverage industry, turbine flow meters play a vital role in ensuring precise dosing and filling processes. The need for accuracy is paramount, especially where hygiene is a concern. When choosing a turbine flow meter for these applications, consider factors such as the meter's compatibility with the fluid being measured and the specific conditions of the installation environment.

Tip: Always check if the turbine flow meter is approved for use in food applications to maintain hygiene standards.

Additionally, turbine flow meters are seeing an increased demand in high-speed batch dosing operations in pharmaceuticals, where accurate flow measurement impacts product quality. For these uses, selecting a model equipped with advanced features can enhance measurement precision and enhance overall system performance.

Tip: Opt for models that offer advanced digital interfaces to improve data accessibility and integration with existing systems.

Factors Affecting the Performance and Calibration of Turbine Meters

Turbine flow meters are widely used in various applications due to their ability to provide accurate flow measurements. However, their performance can be significantly influenced by several factors, such as fluid characteristics, installation conditions, and calibration processes. For instance, viscosity and density of the fluid can alter flow profiles, which in turn affect meter accuracy. According to a study on seepage meters, the design simplicity can lead to performance issues under different hydrologic conditions, drawing parallels to turbine meters where installation errors can similarly impact performance.

Calibration is paramount for ensuring the reliability of flow measurements in turbine meters. Research has indicated that improper calibration methods can lead to discrepancies in readings, especially in gas and liquid applications. For instance, a comparison of calibration techniques for high-performance liquid chromatography emphasized the importance of employing standardized procedures to achieve consistent results. Additionally, advancements in technology, such as the development of calibration facilities for hydrogen-rich gas meters, highlight the evolving demands for precise flow measurement in modern applications. The integration of digital tools for calibration and troubleshooting is also proving essential in improving installation accuracy, as evidenced by recent innovations in flow meter technologies.

Understanding the Mechanisms Behind Turbine Flow Meters - Factors Affecting the Performance and Calibration of Turbine Meters

| Parameter | Description | Impact on Performance | Calibration Frequency |

|---|---|---|---|

| Flow Rate | The volume of fluid that passes through the meter over a specific time period | Affects the rotational speed of the turbine and overall accuracy | Annually |

| Viscosity | The thickness or stickiness of a fluid, affecting flow characteristics | Can lead to measurement errors if not within the meter's specified range | Semi-Annually |

| Density | Mass per unit volume of the fluid | Influences the mass flow calculations and the meter’s calibration | Quarterly |

| Temperature | The thermal condition of the fluid being measured | Can affect the viscosity and density, leading to measurement inaccuracies | Monthly |

| Installation Orientation | The alignment and position of the meter during setup | Improper orientation can lead to turbulence and erroneous readings | As Needed |

Related Posts

-

How to Choose the Right Inline Flow Meter for Your Industrial Applications

-

Innovative Solutions for Inline Water Meter Efficiency Optimization

-

In Depth Comparison of 2 Inch Flow Meters for Diverse Industrial Applications

-

7 Best Flow Meter Types for Accurate Measurement in 2023

-

Exploring the Various Alternative Technologies for Non Contact Flow Meters

-

10 Best Chemical Flow Meters That Improve Accuracy by 95 Percent