Why Choose Magnetic Flow Meters for Accurate Measurement?

Magnetic Flow Meters have become essential for various industries seeking precise fluid measurement. According to a recent report by the Flow Measurement Association, the demand for accurate flow measurement solutions has surged by 15% annually. This trend highlights the critical importance of adopting advanced technologies like Magnetic Flow Meters.

Industry expert Dr. Jake Thompson states, "Magnetic Flow Meters offer unparalleled accuracy in challenging conditions." This accuracy is vital in sectors ranging from water treatment to pharmaceuticals. In these applications, even a minor measurement error can lead to significant financial losses or safety risks. The technology uses electromagnetic fields, eliminating issues faced by traditional flow meters, such as mechanical wear.

However, not all Magnetic Flow Meters are created equal. Some systems might struggle with high viscosity liquids, which could result in inaccurate readings. It’s crucial for businesses to choose the right model tailored to their specific needs. Investing in a quality Magnetic Flow Meter can enhance operational efficiency and reduce long-term costs, making it a wise choice for any organization focused on accuracy.

Understanding Magnetic Flow Meters and Their Functionality

Magnetic flow meters are valuable tools for accurate fluid measurement. They function based on Faraday's law of electromagnetic induction. When a conductive liquid flows through a magnetic field, a voltage is generated. This voltage correlates directly to the flow rate of the liquid. Unlike traditional methods, magnetic flow meters are non-intrusive. They don’t obstruct fluid flow, which helps maintain system efficiency.

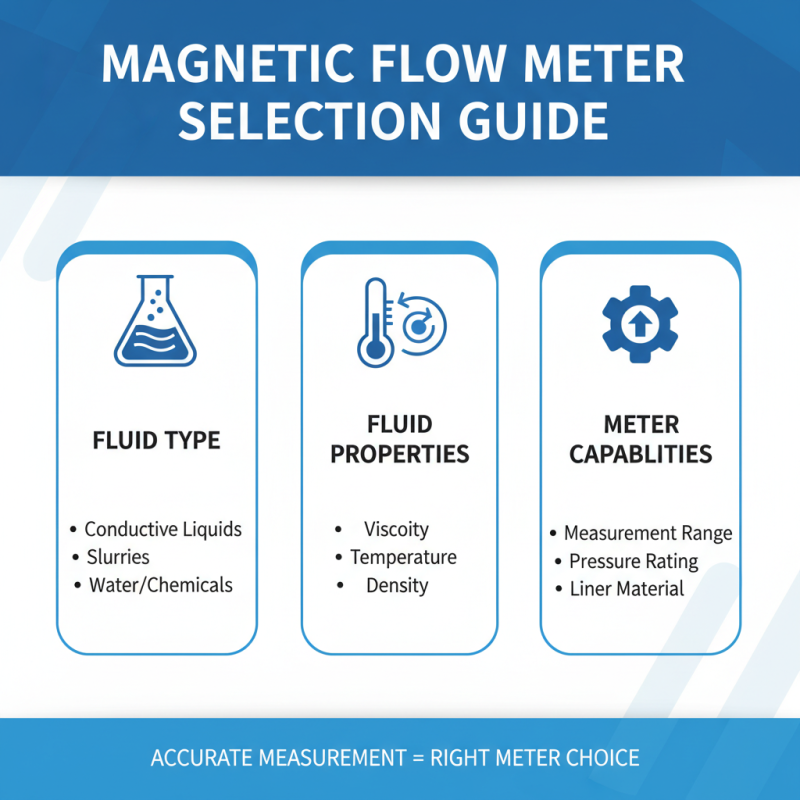

When selecting a magnetic flow meter, consider the conductivity of the fluid. Low-conductivity liquids may yield inaccurate readings. Additionally, temperature and pressure can affect performance. Regular calibration is crucial for maintaining accuracy.

Tips for optimal performance include ensuring proper installation. Align the meter correctly within the piping system. Avoid bends or obstructions near the sensor. Regular maintenance is also key. Clean the sensor when needed, as buildup can impact readings. Lastly, monitor for changes. Alterations in the fluid’s characteristics might call for recalibration. Staying proactive helps ensure reliable, accurate measurements.

Benefits of Using Magnetic Flow Meters for Accurate Measurement

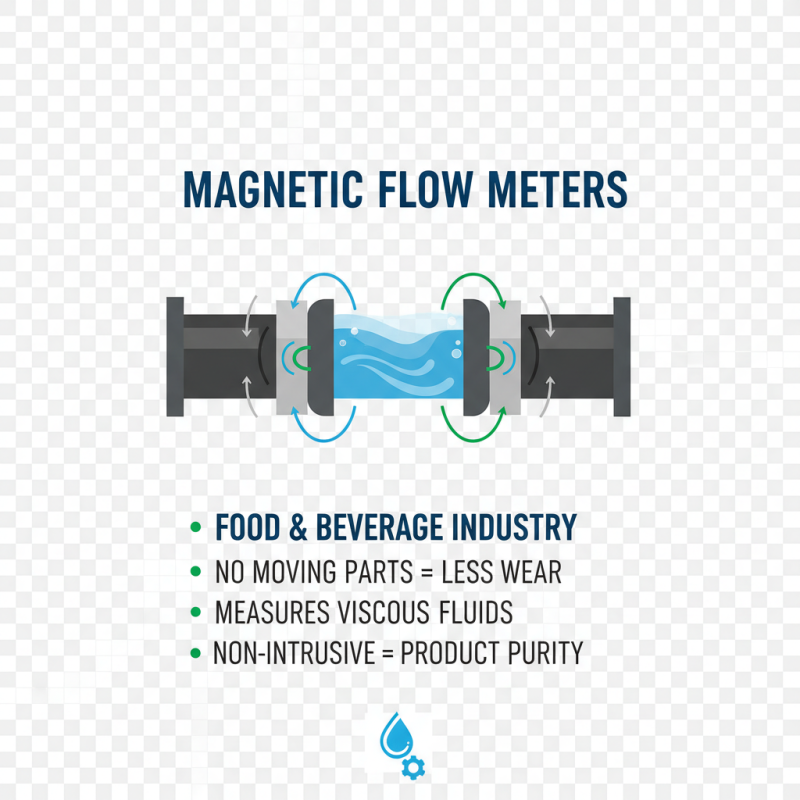

Magnetic flow meters are increasingly popular for liquid measurement. They offer several benefits that enhance accuracy. For starters, they rely on the principle of electromagnetic induction. This principle allows them to measure flow rates without any moving parts. As a result, there is less friction and wear.

According to recent industry reports, magnetic flow meters can achieve an accuracy of ±0.2% of the reading. This level of precision is vital in industries like food and beverage, where compliance is crucial. Additionally, they work well with various conductive liquids, including slurries, making them versatile. However, not all liquids are suitable. Non-conductive fluids pose a challenge.

Maintenance costs are another important factor. Magnetic flow meters typically require less maintenance than mechanical alternatives. This feature results in reduced downtime. Yet, they can be more expensive initially. Some users find this daunting. Balancing the costs with the long-term savings is essential. They may not be the perfect choice for everyone, but their advantages are significant.

Why Choose Magnetic Flow Meters for Accurate Measurement?

| Feature | Description | Benefits |

|---|---|---|

| No Moving Parts | Magnetic flow meters operate with no mechanical components. | Reduced wear and tear, leading to lower maintenance costs. |

| High Accuracy | Provides precise measurements of fluid flow rates. | Essential for applications requiring stringent measurement standards. |

| Wide Application Range | Suitable for various fluids, including corrosive liquids. | Versatile usage in water treatment, food processing, and chemical industries. |

| Minimal Pressure Drop | Designed to not obstruct the flow of fluids. | Ensures energy efficiency and reduces operational costs. |

| Digital Output | Integrates easily with modern control systems. | Enhances data logging and real-time monitoring capabilities. |

Applications of Magnetic Flow Meters in Various Industries

Magnetic flow meters are gaining traction in various industries due to their unique features. In the food and beverage sector, they measure the flow of liquids without any moving parts. This leads to less wear and tear, ensuring consistent measurement even with viscous fluids. Their non-intrusive nature means they maintain the purity of the product, which is essential in this industry.

In the chemical and water treatment industries, these meters can handle a wide range of fluid types. They perform well in corrosive environments, where traditional meters might fail. Their ability to accurately measure flow rates in these challenging conditions is significant. However, the installation can be complex, requiring skilled technicians. Engineers must pay attention to pipe orientation and grounding to avoid inaccuracies.

Moreover, magnetic flow meters are sensitive to changes in the fluid's electrical conductivity. If the conductivity decreases, it may lead to errors. This aspect raises concerns in applications where fluid quality varies frequently. Each industry must evaluate their specific needs and challenges. The importance of accurate flow measurement cannot be overstated, but the path to it has its hurdles.

Key Advantages Over Traditional Flow Measurement Methods

Magnetic flow meters are gaining popularity for their precision. They use electromagnetic principles to measure flow. This method is often more accurate than traditional systems like mechanical flow meters. Mechanical devices can wear out over time, leading to measurement errors. Magnetic flow meters do not have moving parts, reducing potential for wear and tear.

One key advantage is their versatility. They can measure conductive liquids in various industries. This includes water treatment and food processing. Their robust design makes them suitable for harsh environments. Additionally, magnetic flow meters maintain accuracy across a wide range of flow rates. Traditional meters can struggle under varying conditions, causing fluctuations in readings.

However, there are some limitations to consider. Magnetic flow meters require a minimum flow rate to function correctly. If flow is too low, accuracy decreases. Also, they can only measure conductive liquids. Non-conductive fluids, such as oils, cannot be measured. Users should reflect on their specific needs to determine the best flow measurement solution.

Factors to Consider When Choosing a Magnetic Flow Meter

When choosing a magnetic flow meter, several factors come into play. First, consider the fluid type. Different liquids affect the readings. Slurry and conductive fluids behave uniquely. The viscosity and temperature of the fluid also impact measurement accuracy. Choosing a meter that can handle these variables is crucial.

Another critical aspect is the installation environment. Space constraints and piping configurations can pose challenges. Ensure that the magnetic flow meter fits seamlessly into existing systems. Check the meter's size and connection options. Material compatibility is essential too. Meters must withstand the chemical properties of the fluids they measure.

Lastly, think about the maintenance and calibration requirements. Regular checks are essential for accuracy. A meter with simpler maintenance may save time and costs. However, consider if the user is equipped to handle these tasks. Sometimes, opting for advanced features may create complications. Balancing performance with practicality is key in your selection process.

Related Posts

-

Top 10 Tips for Choosing the Right Electromagnetic Flow Meter for Your Needs

-

The Future of Flow Meters Technology Trends and Their Impact on Industrial Efficiency

-

How to Choose the Right Inline Flow Meter for Your Industrial Applications

-

5 Reasons Why the 2 Inch Flow Meter is a Game Changer for Your Industry

-

Top 10 Flow Rate Meters for Accurate Measurement and Performance Evaluation

-

How to Choose the Right Mag Meter for Your Industrial Applications