How to Choose the Right Gas Flow Meter for Your Industrial Applications

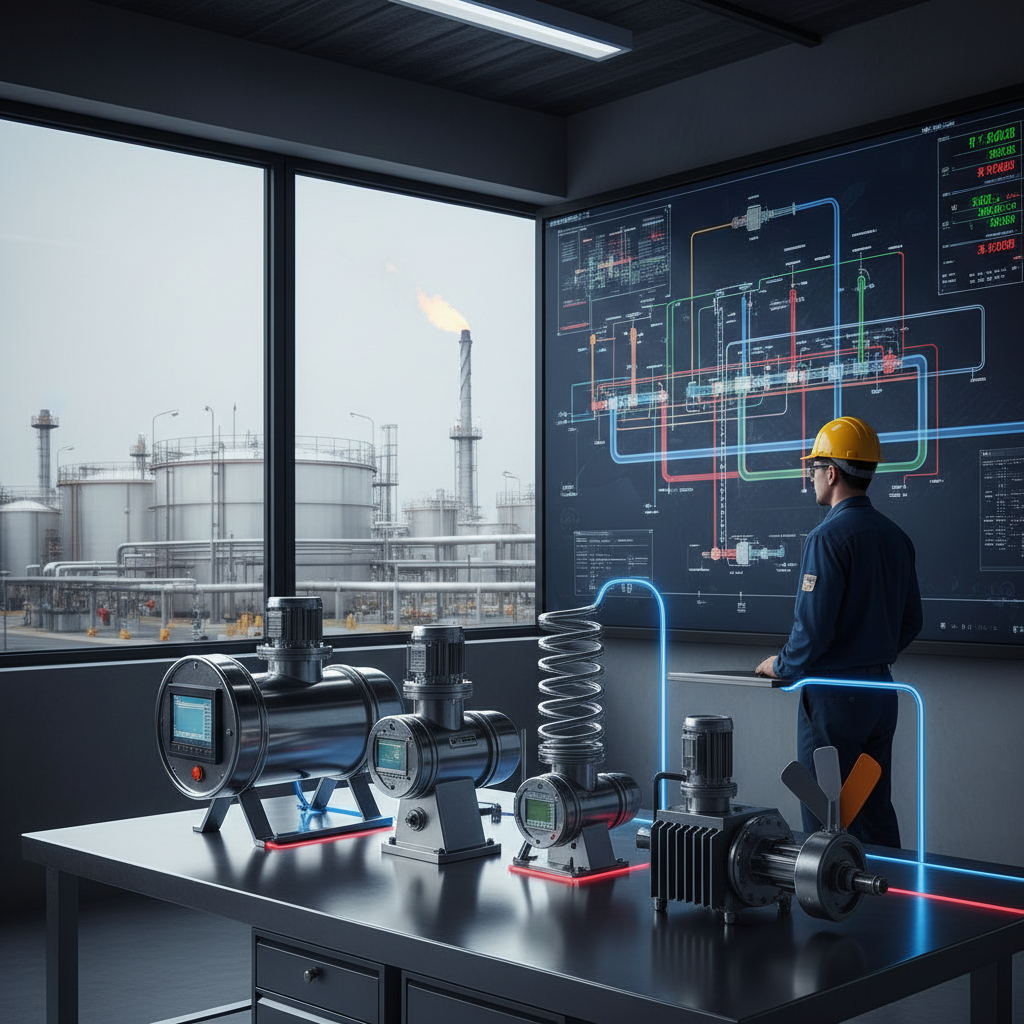

Selecting the appropriate Gas Flow Meter for industrial applications is crucial for ensuring efficiency and accuracy in measurement processes. With a variety of options available, understanding the unique requirements of your operation is essential. This guide aims to provide valuable insights and tips on navigating the selection process for a gas flow meter, helping you make informed decisions that align with your specific application needs.

In the ever-evolving industrial landscape, the demand for precise flow measurement is increasing significantly. A suitable gas flow meter not only enhances operational efficiency but also contributes to safety and cost-effectiveness. Factors such as flow range, accuracy, pressure drop, and installation environment should be carefully considered to choose the right meter. By evaluating these critical components, industries can optimize their processes and achieve better regulatory compliance.

Ultimately, the right gas flow meter can lead to improved operational performance and reduced downtime, making it a vital investment for any industrial setup. This article will explore essential tips and strategies to facilitate a seamless selection process, ensuring that your chosen gas flow meter caters to the specific demands of your application.

Understanding the Different Types of Gas Flow Meters for Industry Use

Selecting the appropriate gas flow meter for industrial applications requires a nuanced understanding of the various types available in the market. The global demand for wet gas meters signifies the growing importance of accurate measurement in industrial sectors. This market is projected to surge from $4.18 billion in 2025 to $6.29 billion by 2032, reflecting a compound annual growth rate (CAGR) of 6.00%. Such growth underscores the critical need for precise gas flow measurement technologies, particularly in environments like natural gas delivery, which has seen a noticeable increase of 6.89% in flow to industries in Iran over a short period.

Among the different types of gas flow meters, mass flow controllers play a significant role in controlling process gases, particularly in the semiconductor industry, where flow rates can range from as low as 10 μL/min to 1 L/min. The empirical nature of process gas control in semiconductor fabrication emphasizes the necessity for flow meters that can provide accurate and reliable measurements under varying conditions. Additionally, advancements in ultrasonic flow meter verification technologies indicate a move toward more sophisticated solutions for custody transfer, ensuring compliance and precision in gas measurement across various industries.

Key Factors to Consider When Selecting a Gas Flow Meter

Choosing the right gas flow meter for your industrial applications is critical to ensuring efficiency and accuracy in fluid measurement. When selecting a gas flow meter, there are several key factors to consider. First, understanding the flow type—whether it is wet gas, dry gas, or a mixture—plays a significant role. The global wet gas meters market is projected to grow from $4.18 billion in 2025 to $6.29 billion by 2032, indicating a strong demand for accurate measurement solutions in industrial settings.

Additionally, the technology type is essential; for example, Coriolis flow meters are gaining popularity due to their capability to provide multi-parameter measurements across various fluids. This extensive portfolio of Coriolis meters is particularly advantageous as industries seek high-performance solutions that can adapt to diverse applications.

**Tips:** Always consider the operational environment when choosing a gas flow meter. Factors such as temperature, pressure, and fluid composition can significantly impact performance. Moreover, ensure that the selected meter complies with industry standards and regulations to maintain operational integrity. Regular calibration and maintenance of the flow meter are also critical to ensuring long-term reliability and accuracy.

How to Choose the Right Gas Flow Meter for Your Industrial Applications - Key Factors to Consider When Selecting a Gas Flow Meter

| Criteria | Description | Examples |

|---|---|---|

| Measurement Range | The range of gas flow rates the meter can measure. | 0-100 L/min, 0-5000 SCFM |

| Gas Type | The specific type of gas being measured, which can affect meter selection. | Natural gas, nitrogen, propane |

| Accuracy | The degree of precision in the measurement results. | ±0.5%, ±1% |

| Operating Pressure | The maximum pressure at which the flow meter can operate. | Up to 100 psi, 1500 psig |

| Temperature Range | The range of temperatures the flow meter can handle. | -40 to 150°C, 0 to 200°F |

| Installation Type | How the meter is installed in the system. | Inline, insertion |

| Output Signal | The type of signal output for integration with control systems. | 4-20 mA, pulse output |

Comparative Analysis of Leading Gas Flow Meter Brands in 2025

In 2025, the gas flow meter market is characterized by fierce competition among leading brands, each offering unique features and innovations. Prominent manufacturers include ABB, Endress+Hauser, and Siemens.

ABB is noted for its advanced ultrasonic flow meters, which provide high accuracy for a variety of gas types. These meters are well-suited for applications requiring precise measurements and are equipped with advanced diagnostics to ensure reliability.

On the other hand, Endress+Hauser has made strides with its electromagnetic flow meters, which excel in handling challenging flow conditions. Their meters are designed for easy installation and maintenance, which is a significant advantage for industries looking to minimize downtime.

Siemens offers a diverse range of thermal mass flow meters, praised for their robustness and ability to measure both very low and high flow rates effectively. Their technology is particularly beneficial in high-temperature environments, solidifying their position in sectors like oil and gas.

When selecting the right gas flow meter, it is crucial to consider specific application requirements such as flow range, accuracy, and operating conditions. The comparative strengths of ABB, Endress+Hauser, and Siemens highlight the importance of aligning the technological capabilities of a flow meter with the needs of your industrial process, ensuring efficient and accurate gas measurement.

Best Practices for Installing and Calibrating Gas Flow Meters

When it comes to installing and calibrating gas flow meters in industrial settings, meticulous attention to detail is paramount for optimal performance. The first step is to ensure that the flow meter is installed in an appropriate location, away from obstructions that could disrupt flow patterns. Vertical or horizontal installation should be chosen based on the manufacturer's specifications, as improper installation can lead to inaccurate readings.

Tips: Always refer to the specific manufacturer's guidelines for installation height and orientation to prevent issues later. Proper grounding of the meter is also crucial to avoid electromagnetic interference, which can skew measurements.

Calibration is another critical aspect that cannot be overlooked. It is essential to use a calibrated reference meter during the calibration process to ensure accuracy. Regular calibration checks should be scheduled to maintain precision, especially in dynamic processes where gas composition or flow rate might change frequently.

Tips: Document each calibration procedure thoroughly, including the conditions under which calibration was performed, to maintain records for compliance and quality control. Make use of computerized systems for easier tracking and to facilitate timely reminders for recalibration.

Future Trends in Gas Flow Meter Technology for Industrial Applications

In the evolving landscape of industrial applications, choosing the right gas flow meter is crucial. The forecast for smart flow meters indicates a substantial growth, with the global market expected to reach $2.83 billion by 2025 and further rise to $3.84 billion by 2033, reflecting a compound annual growth rate (CAGR) of 3.9%. Notably, the ultrasonic flow meter market is set to expand from $2.08 billion in 2025 to $3.07 billion by 2032, showcasing a robust CAGR of 5.5%. This growth mirrors the increasing demand for precise and efficient measurement technologies across various sectors.

As industries delve deeper into energy solutions, hydrogen storage and transportation present a lucrative market potential, estimated to be in the hundreds of billions. This sector is pivotal, acting as the link between hydrogen production and demand, indicating a significant shift towards sustainable energy practices. Moreover, the oil field integrity management market is projected to increase from $15.61 billion in 2025 to $26.18 billion by 2032, with a notable growth rate of 7.67%.

**Tips:** When selecting a gas flow meter, consider the specific application and operational environment. Ensure the chosen flow meter can handle the required measurement range and fluid properties. Additionally, keep an eye on emerging technologies, as innovations can significantly enhance measurement accuracy and efficiency.

Related Posts

-

Ultimate Guide to Understanding Gas Flow Meter Variations for Optimal Selection

-

10 Best Chemical Flow Meters That Improve Accuracy by 95 Percent

-

7 Essential Flow Meter Types Every Industry Should Know

-

How to Select the Right Mechanical Flow Meter for Your Industrial Needs

-

How to Choose the Right Non Contact Flow Meter for Accurate Measurement in Industrial Applications

-

Understanding the Importance of Mechanical Flow Meters in Modern Industrial Applications