How to Choose the Right Flow Meter for Your Needs?

Choosing the right Flow Meter can be a daunting task. There are many options available. Each type serves different purposes and applications. Understanding your needs is crucial. Factors such as fluid type, flow rate, and temperature matter greatly.

Flow Meters vary in design and function. Some are ideal for water, while others suit oils or chemicals. Each application requires specific features. Accuracy is essential for precise measurements. A poorly chosen Flow Meter can lead to costly mistakes.

Consider both budget and performance. An expensive Flow Meter doesn't always equal better results. It's important to reflect on what you truly need. Research is vital. Take time to compare different models and various manufacturers. In the end, the best choice depends on your unique requirements.

Understanding Different Types of Flow Meters and Their Applications

When selecting a flow meter, understanding the different types is crucial. Flow meters come in various styles, each suited for specific applications. For instance, mechanical meters are often used for water, while electromagnetic meters work well with conductive liquids. Recognizing your fluid's characteristics helps determine the best option.

Tips: Assess the nature of your fluid first. Is it viscous or thin? This factor can significantly impact the meter's accuracy.

Moreover, consider the installation requirements. Some meters need straight pipe runs, while others can be installed in tight spaces. Don't overlook the maintenance aspect either. Some devices may require more frequent calibration or cleaning.

Tips: Think about ease of access for maintenance. Accessibility can save time and reduce costs. Remember, no single meter is perfect for every situation. Evaluate your needs carefully.

Flow Meter Types and Their Applications

Key Parameters to Consider When Selecting a Flow Meter

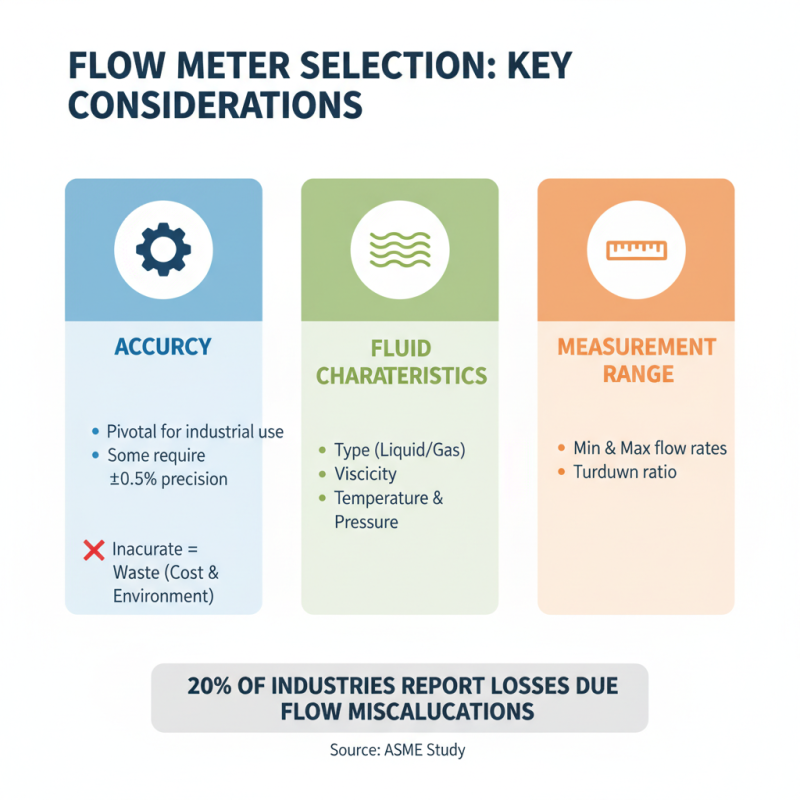

When selecting a flow meter, consider parameters like accuracy, range, and fluid characteristics. Accuracy is pivotal; some industrial applications require a precision of ±0.5%. An inaccurate reading can lead to waste, affecting both costs and environmental compliance. A study from the American Society of Mechanical Engineers highlights that 20% of industries report losses due to miscalculations in flow measurement.

Another critical aspect is the flow rate range. Different applications may have varying flow rates, from a few milliliters per minute to thousands of liters per hour. For instance, choosing a meter with an inadequate range can lead to false readings. A survey from the Flow Measurement Society showed that 15% of users faced challenges because of mismatched flow rates.

Fluid characteristics also matter significantly. Viscosity, temperature, and density can impact flow meter performance. A flow meter suitable for water may not work for oil due to differences in viscosity. About 30% of users have regretted ignoring these factors. This oversight often results in increased maintenance costs and operational inefficiencies.

Evaluating Accuracy, Range, and Resolution in Flow Measurement

Choosing a flow meter requires careful consideration. Accuracy is crucial, especially in critical applications. A flow meter that lacks precision can lead to costly errors. Evaluate the specifications provided by different models. Check their stated accuracy percentage. A meter with high accuracy will often provide better measurements in varied conditions.

Range is another vital factor. It defines the lowest and highest flow rates the meter can accurately measure. If you need to monitor both low and high flows, ensure the selected device covers this range. A narrow range can limit your application. Consider your specific requirements to avoid potential issues.

Resolution impacts the smallest change in flow that the meter can detect. High resolution is necessary for detailed flow analysis. Some applications may not require extremely high resolution. Reflect on your needs to avoid overspending on features you might not use. Balancing accuracy, range, and resolution can be tricky. A detailed analysis will help you find the right choice for effective flow measurement.

Cost vs. Performance: Budgeting for Your Flow Meter Needs

Choosing the right flow meter involves balancing cost and performance. Many people underestimate the impact of budget on their decision. A low-cost meter might save money initially but could lead to higher costs over time due to inaccuracies or increased maintenance. Performance often relates directly to how well the meter fits specific needs.

When evaluating options, consider the accuracy required for your application. Some processes need precise measurements, while others can tolerate more variability. Investing in a high-performance meter may be advantageous in the long run. However, if your budget is tight, you might need to compromise on certain capabilities.

While it’s tempting to select the cheapest option, this could backfire. A poorly chosen meter often leads to frustration and additional costs. Reflecting on your specific requirements can help clarify what balance of cost and performance is right for you. Achieving the perfect fit often requires assessing both your current and future needs.

How to Choose the Right Flow Meter for Your Needs? - Cost vs. Performance: Budgeting for Your Flow Meter Needs

| Flow Meter Type | Typical Cost ($) | Accuracy (%) | Application | Maintenance Level |

|---|---|---|---|---|

| Coriolis | $3,000 - $10,000 | ±0.1% | Food & Beverage | Low |

| Magnetic | $1,500 - $5,000 | ±0.5% | Water Treatment | Medium |

| Positive Displacement | $500 - $2,000 | ±0.5% | Oil & Gas | Medium |

| Ultrasonic | $2,000 - $8,000 | ±1.0% | HVAC | Low |

| Turbine | $1,000 - $3,000 | ±0.5% | Chemical | Medium |

Industry Standards and Compliance Requirements for Flow Meters

When selecting a flow meter, it’s crucial to consider industry standards and compliance requirements. Different industries have specific regulations that dictate flow measurement accuracy. For instance, the food and beverage sector often mandates meters that meet sanitary standards. This ensures that products remain uncontaminated and safe for consumption.

Compliance can be complicated. There are many standards like ISO, API, or ANSI. Each has its own criteria for calibration, installation, and maintenance. Some industries have rigorous testing protocols. If these standards are not met, it can lead to costly rework or fines. This aspect often gets overlooked during the selection process, but it should not.

Additionally, consider how frequently the meter needs to be recalibrated. Neglecting regular checks can result in inaccurate measurements. Understanding the compliance landscape is vital. It affects both operational efficiency and product quality. Ignoring these details may seem less urgent, yet it can undermine the entire system.

Related Posts

-

How to Choose the Right Inline Flow Meter for Your Industrial Applications

-

Ultimate Guide to Choosing the Best Inline Flow Meter for Your Industrial Needs

-

Ultimate Guide to Understanding Different Flow Meter Types for Your Business Needs

-

7 Expert Tips for Selecting the Best Mag Meter for Your Industry

-

Ultimate Guide to Understanding Gas Flow Meter Variations for Optimal Selection

-

10 Best Chemical Flow Meters That Improve Accuracy by 95 Percent