How to Choose the Right Oil Flow Meter for Your Industrial Needs in 2025

In the rapidly evolving industrial landscape of 2025, the need for precision in monitoring and controlling the flow of oil has never been more critical. As industries strive for efficiency and sustainability, selecting the right Oil Flow Meter becomes a pivotal decision that can significantly impact operational performance. According to Dr. Emily Carter, a renowned expert in fluid dynamics, "Choosing the right Oil Flow Meter is not just about accuracy; it's about aligning technology with your operational goals."

As businesses navigate the complexities of advanced technology and increasing environmental regulations, the selection process for an Oil Flow Meter must be approached with careful consideration. With a wide array of options available, understanding the unique requirements of your operations is essential to ensure optimal performance. Whether it's for accuracy, range, or compatibility, discerning the features that best match your industrial needs can lead to enhanced productivity and cost savings.

This guide aims to distill the critical factors that should influence your decision-making process in choosing the right Oil Flow Meter. By focusing on both technical specifications and application scenarios, we will empower industries to make informed choices tailored to their specific requirements in the dynamic environment of 2025.

Understanding Oil Flow Meter Types for Industrial Applications

When selecting the right oil flow meter for industrial applications, understanding the various types available is crucial.

The three primary types of oil flow meters are positive displacement, turbine, and mass flow meters, each offering unique advantages suited for different operational requirements.

According to the "Global Oil Flow Meter Market" report published by MarketsandMarkets, the positive displacement flow meter is highly favored for its precision in low flow rates and varied viscosities, making it ideal for applications in sectors like chemical processing where accuracy is paramount.

Turbine flow meters, on the other hand, are typically preferred in high-speed applications where reliability and ease of use are critical. The same report indicates that turbine meters account for a significant market share due to their ability to provide rapid measurements and low-pressure drops, which is essential for maintaining system efficiency in oil refining and transportation.

Furthermore, mass flow meters, particularly Coriolis type, are becoming increasingly popular due to their ability to measure mass flow directly and accurately across a wide range of temperatures and pressures. As industries increasingly seek to enhance efficiency, the market for these advanced metering solutions is projected to grow at a compound annual growth rate (CAGR) of 6.5% through 2025.

Industries must also consider the environmental impact and accuracy standards when choosing a flow meter. The American Petroleum Institute (API) recommends specific calibration protocols that aid in maintaining consistency and integrity in measurements. Selecting a flow meter that adheres to these guidelines not only ensures compliance but also boosts process reliability and sustainability in oil handling and processing applications.

Key Factors to Consider When Selecting an Oil Flow Meter

When selecting an oil flow meter for industrial applications, several key factors must be taken into account to ensure optimal performance and reliability. One of the primary considerations is the meter's compatibility with the specific type of oil being measured. Different oils possess varying viscosities and chemical compositions, which can influence the flow meter's accuracy. Therefore, understanding the properties of the oil—such as temperature range, viscosity, and potential for particulate contamination—is crucial in narrowing down the choices and selecting a meter designed to handle these particular characteristics.

Another important factor is the flow rate requirements of the application. Oil flow meters are available in various designs and technologies, each suited for different flow ranges. Users need to assess their operational requirements, including maximum and minimum flow rates, to choose a meter that provides accurate measurements across the intended range. Additionally, consideration should be given to the installation environment; factors such as the available space, temperature, pressure conditions, and the need for remote monitoring can impact the type of flow meter that will be most effective. By carefully evaluating these factors, industries can make informed decisions that enhance operational efficiency and accuracy in oil measurement.

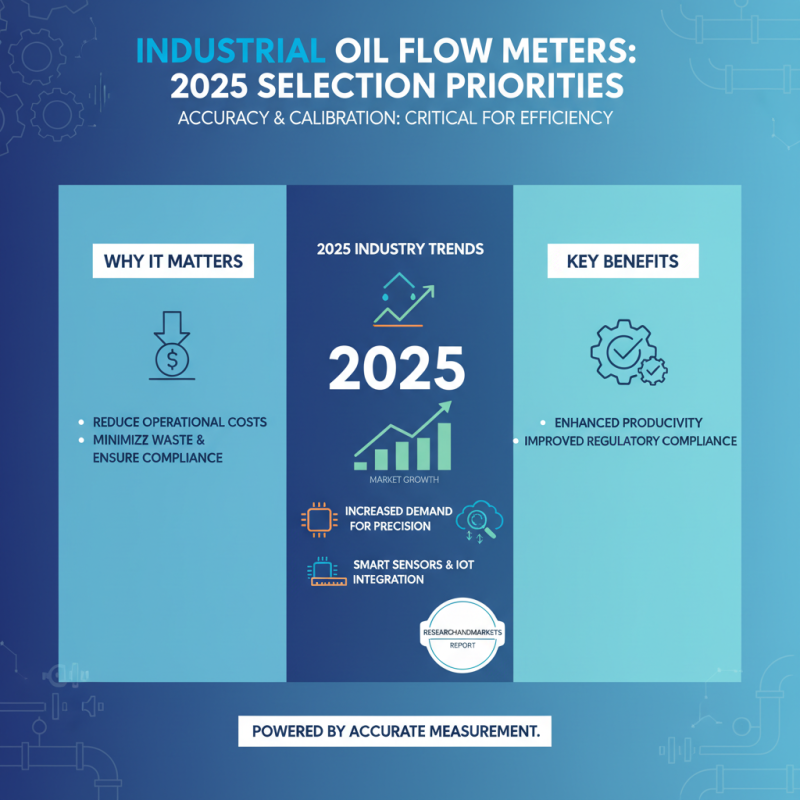

Oil Flow Meter Selection: Key Factors in 2025

This bar chart illustrates the key factors to consider when selecting an oil flow meter in 2025, focusing on their relative importance levels. Accuracy and compatibility are the highest priority, while cost is relatively less critical compared to other factors.

Evaluating Accuracy and Calibration Needs for Your Flow Meter

When selecting an oil flow meter for industrial applications, the importance of evaluating accuracy and calibration needs cannot be overstated. In 2025, industries will increasingly prioritize precise measurements due to the rising demand for efficiency and productivity. A report from ResearchAndMarkets indicates that the oil and gas flow meter market is expected to grow significantly, driven by the need for enhanced measurement accuracy and the integration of advanced technologies such as smart sensors and IoT devices. Accurate flow measurement can reduce operational costs by minimizing wastage and ensuring compliance with regulatory standards.

Calibration is a critical aspect that determines the reliability of flow measurements in various applications. According to the American Petroleum Institute (API), regular calibration is essential for maintaining measurement accuracy, with recommended intervals depending on the type of meter and application. For instance, positive displacement meters require calibration every six months, while Coriolis meters may need calibration annually. Failure to schedule regular calibration not only risks operational inefficiencies but could also lead to costly penalties for non-compliance with industry regulations. Thus, businesses should consider the specific calibration requirements of potential flow meters when making their selection to ensure long-term operational efficiency and regulatory compliance.

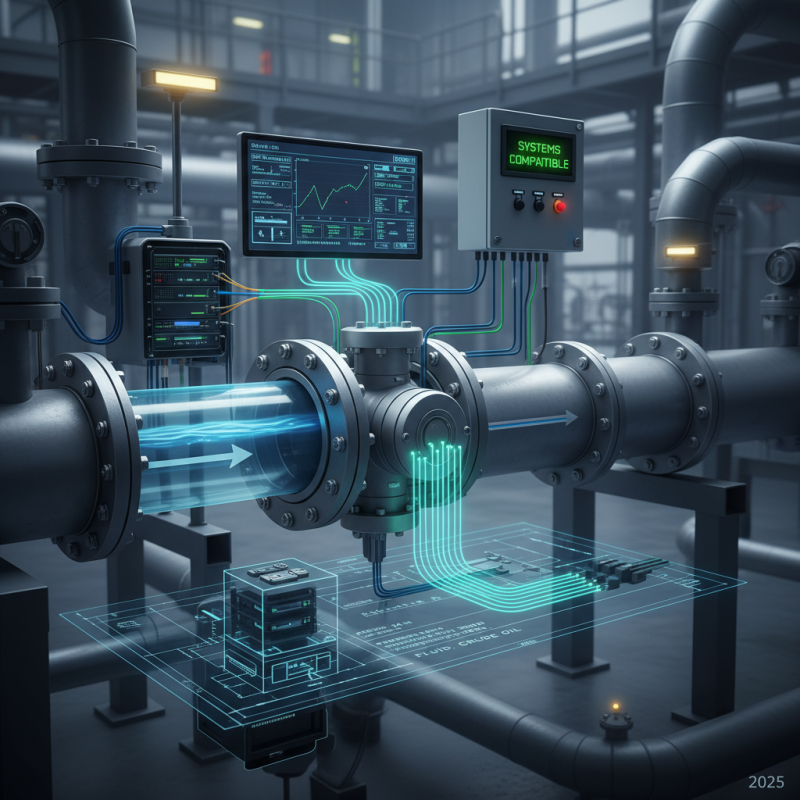

Assessing Compatibility with Existing Systems and Infrastructure

When selecting the right oil flow meter for industrial applications in 2025, it is crucial to evaluate its compatibility with existing systems and infrastructure. Begin by reviewing the specifications of your current piping system, including pipe diameter, pressure ratings, and fluid characteristics. Understanding these parameters helps in identifying flow meters that can seamlessly integrate, thereby minimizing installation complications and potential downtime. Additionally, consider the communication protocols used in your existing setup, as flow meters need to communicate effectively with control systems and data acquisition tools to provide accurate readings.

Another important aspect to assess is the physical layout of your facility. The flow meter's size, installation orientation, and maintenance accessibility must align with your infrastructure constraints. Before finalizing a choice, conduct a thorough analysis of environmental conditions such as temperature fluctuations and potential exposure to contaminants, as these factors can influence the performance and longevity of the flow meter. By prioritizing compatibility with your existing systems, you not only ensure operational efficiency but also safeguard your investment against future technical challenges.

Future Trends in Oil Flow Meter Technology for 2025 and Beyond

As the industrial landscape evolves, the demand for advanced oil flow meter technology continues to surge. In 2025, we anticipate significant advancements driven by increased automation and the integration of IoT technologies. Smart oil flow meters equipped with sensors will not only provide real-time data but will also enhance connectivity and interoperability within the manufacturing systems. These devices are expected to seamlessly communicate with control systems, allowing for improved monitoring, predictive maintenance, and data analysis capabilities.

Moreover, the use of artificial intelligence in oil flow metering is set to revolutionize the industry by optimizing measurement accuracy and efficiency. AI algorithms can analyze flow patterns and operational data to forecast potential issues before they arise, thus minimizing downtime. Additionally, the increasing focus on sustainability will push manufacturers to develop more eco-friendly and energy-efficient flow meters, promoting greener practices in oil and gas production. The adoption of these technological trends will not only address current industry challenges but also shape the future landscape of oil flow measurement.

How to Choose the Right Oil Flow Meter for Your Industrial Needs in 2025

| Meter Type | Accuracy | Flow Range | Operating Pressure | Temperature Range | Application |

|---|---|---|---|---|---|

| Mechanical Meter | ±2% | 0.1 - 1000 L/min | Up to 10 bar | -20 to 80°C | General Industrial |

| Coriolis Meter | ±0.1% | 0.5 - 2000 kg/h | Up to 25 bar | -50 to 150°C | Food & Beverage, Chemicals |

| Ultrasonic Meter | ±0.5% | 1 - 5000 L/min | Up to 16 bar | -40 to 100°C | Water, Oil, Gas |

| Magnetic Meter | ±0.2% | 1 - 2000 L/min | Up to 16 bar | -25 to 90°C | Water, Slurries |

| Positive Displacement Meter | ±0.5% | 0.2 - 500 L/min | Up to 300 bar | -10 to 50°C | Heavy Oil, Chemicals |

Related Posts

-

Ultimate Guide to Choosing the Best Inline Flow Meter for Your Industrial Needs

-

How to Choose the Right Paddle Wheel Flow Meter for Your Industrial Applications

-

Top 10 Flow Rate Meters for Accurate Measurement and Performance Evaluation

-

The Future of Flow Meters Technology Trends and Their Impact on Industrial Efficiency

-

Comprehensive Guide to Selecting the Right Gas Flow Meter for Your Business Needs

-

Understanding the Benefits of Turbine Meters in Modern Industry Applications