How to Effectively Choose the Right Air Flow Meter for Your Industrial Needs

In today's industrial landscape, the importance of accurately measuring air flow cannot be overstated, particularly in optimizing processes and ensuring compliance with regulatory standards. According to a report by MarketsandMarkets, the air flow meter market is projected to reach $6.7 billion by 2025, growing at a CAGR of 5.5%. Selecting the right Air Flow Meter is crucial for various applications, including HVAC systems, chemical processing, and environmental monitoring. With advancements in technology, there are numerous types of air flow meters available, each designed for specific measurement needs and operational conditions. To effectively choose an air flow meter that aligns with your industrial requirements, it is essential to consider factors such as accuracy, range, and compatibility with existing systems. This guide will provide insights into the vital considerations for selecting the optimal air flow meter for your unique applications, ensuring efficient performance and cost-effectiveness.

Factors to Consider When Selecting an Air Flow Meter for Industrial Applications

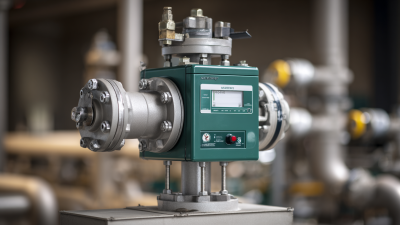

When selecting the right air flow meter for industrial applications, it is crucial to consider several key factors that can significantly impact the effectiveness of compressed air flow measurement. One of the most important criteria is the type of flow meter based on the nature of the gas or air being measured. Different flow meters, such as vortex, thermal, or differential pressure meters, offer unique advantages depending on the specific requirements of your application, such as accuracy, range, and installation constraints.

Another critical factor to take into account is the compatibility of the flow meter with the operating conditions, including pressure, temperature, and the presence of contaminants. The material of the meter should also be suitable for the medium being measured to ensure longevity and reliability.

**Tips:**

- Always evaluate the measurement accuracy required for your specific application; this can guide you in selecting the most suitable flow meter technology.

- Consider the ease of installation and maintenance of the chosen device, as these factors can influence operational efficiency and downtime in industrial settings.

How to Effectively Choose the Right Air Flow Meter for Your Industrial Needs

| Measurement Principle | Suitable Applications | Accuracy (%) | Flow Range (m³/h) | Temperature Range (°C) | Pressure Range (bar) |

|---|---|---|---|---|---|

| Differential Pressure | HVAC, Industrial Exhaust | ±1.5 | 0.5 - 2000 | -20 to 120 | 0 to 10 |

| Thermal Mass | Industrial Process, Gas Measurement | ±2.0 | 0.1 - 500 | -20 to 180 | 0 to 6 |

| Ultrasonic | Natural Gas, Air Handling | ±1.0 | 0.5 - 1000 | -40 to 60 | 0 to 9 |

| Positive Displacement | Biodigesters, Low-flow Applications | ±0.5 | 0.01 - 100 | -20 to 150 | 0 to 5 |

Understanding Different Types of Air Flow Meters: Pros and Cons for Industry Use

When selecting an air flow meter for industrial applications, understanding the various types and their respective pros and cons is essential for optimal performance. First, there are differential pressure flow meters, which are widely used due to their simplicity and reliability. They measure the pressure drop across an orifice or a venturi, providing accurate readings for gases and liquids. However, they can be influenced by temperature and pressure changes, which may affect the precision in certain conditions.

Lastly, vortex flow meters, which rely on the principle of vortices generated by an obstacle in the flow path, are known for their versatility and suitability in various conditions. However, they can struggle with low-flow accuracy and might not be ideal for all gas types. Understanding these different flow meter technologies and their trade-offs will help industries make informed choices tailored to their specific needs.

Evaluating Measurement Accuracy: Standards and Specifications for Air Flow Meters

When selecting an air flow meter for industrial applications, understanding measurement accuracy is paramount. The accuracy of air flow meters is often dictated by various standards and specifications set by regulatory bodies. Common standards include ISO 5167 for differential pressure flow meters and AGA reports for gas flow measurement. These guidelines not only ensure consistency across instruments but also provide a benchmark for reliability and precision.

Evaluating specifications such as rangeability, which represents the ratio between the maximum and minimum measurable flow, is crucial in determining how well the meter will perform under varying operational conditions. Furthermore, calibration processes and traceability to national standards can significantly impact measurement accuracy. Manufacturers often provide detailed specifications that include accuracy classes and expected uncertainties, allowing users to make informed choices based on their unique industrial needs and application environments.

Air Flow Meter Measurement Accuracy Comparison

The Role of Calibration and Maintenance in Ensuring Accurate Air Flow Measurement

Calibration and maintenance are critical components in ensuring accurate air flow measurement in industrial applications. Regular calibration of air flow meters helps to align the device’s readings with the true air flow conditions. Calibration should be performed according to the manufacturer's specifications and can involve comparing the output of the meter to a known standard. This process not only verifies the accuracy of the readings but also identifies any drift in the measurements that may occur over time, allowing for timely corrective actions.

Maintenance practices complement calibration by ensuring that the air flow meter operates optimally. Regular cleaning, inspection, and replacement of parts such as filters and sensors can prevent the accumulation of debris and contaminants that may affect performance. Establishing a routine maintenance schedule based on the specific operating environment and meter type is essential. By prioritizing both calibration and maintenance, industries can achieve reliable air flow measurements, leading to improved process control, efficiency, and safety.

Cost-Benefit Analysis: Upfront Investment vs. Long-Term Savings in Air Flow Measurement

In selecting the right air flow meter for industrial applications, conducting a cost-benefit analysis is crucial. The initial investment in high-quality air flow measurement devices can be substantial, with advanced technologies such as thermal mass flow meters or Coriolis flow meters costing between $1,000 to $10,000 or more, depending on specifications and accuracy requirements. However, the long-term savings generated by improved accuracy and efficiency often outweigh these upfront costs. According to a report by the International Society of Automation, implementing precise flow measurement systems can reduce energy costs by up to 15%, resulting in significant financial returns over time.

Moreover, accurate air flow measurement plays a vital role in compliance and operational efficiency. As per a study published by the Energy Efficiency and Renewable Energy (EERE) division of the U.S. Department of Energy, industries with optimized flow measurement systems have reported a reduction in operational costs by approximately 25% through enhanced process controls and reduced material waste. This illustrates that while the upfront costs of high-quality air flow meters may seem daunting, the potential for long-term operational savings and improved efficiency makes them a worthwhile investment for industrial sectors aiming for sustainability and economic viability.

Related Posts

-

Comprehensive Guide to Selecting the Right Gas Flow Meter for Your Business Needs

-

Ultimate Guide to Understanding Different Flow Meter Types for Your Business Needs

-

The Ultimate Guide to Understanding Flow Meters and Their Impact on Industrial Efficiency

-

Understanding the Mechanisms Behind Turbine Flow Meters

-

7 Expert Tips for Selecting the Best Mag Meter for Your Industry

-

9 Proven Reasons Why Mechanical Flow Meters Are the Best Choice for Accurate Measurements