Why Choose an Inline Flow Meter for Accurate Fluid Measurement

In the realm of fluid measurement, accuracy and reliability are paramount. Among the various instruments available, the Inline Flow Meter has emerged as a crucial device for industries that depend on precise fluid control. This type of flow meter is designed to be integrated directly into the piping system, allowing for real-time monitoring of fluid dynamics without interrupting the flow. The accuracy offered by Inline Flow Meters is vital for applications ranging from chemical processing to water treatment, ensuring that operations run smoothly and efficiently.

One of the key advantages of using an Inline Flow Meter is its ability to provide immediate feedback on flow conditions, which aids in optimizing processes and minimizing waste. By delivering accurate readings, these meters help in maintaining the desired flow rates and pressures, thereby enhancing overall system performance. Furthermore, Inline Flow Meters often feature advanced technology that reduces the chances of measurement errors, making them a preferred choice among engineers and operators alike.

As industries continue to evolve and demand higher efficiency, the role of Inline Flow Meters in fluid measurement becomes increasingly significant. Their integration not only supports compliance with stringent regulations but also contributes to cost-effective production and sustainability efforts. Thus, understanding the benefits and functionalities of Inline Flow Meters is essential for professionals seeking to enhance their fluid management strategies.

Understanding Inline Flow Meters and Their Functionality

Inline flow meters play a crucial role in various industries where precise fluid measurement is vital. These devices are designed to measure the flow rate of liquids and gases directly as they pass through a pipeline, ensuring real-time, accurate data collection. According to industry studies, using inline flow meters can lead to a reduction in measurement errors by as much as 20%, significantly improving operational efficiency. This is particularly important in sectors such as food and beverage, pharmaceuticals, and chemical processing, where accuracy is essential to comply with safety regulations and maintain product quality.

Inline flow meters operate based on different principles, including electromagnetic, ultrasonic, and mechanical methods, each suitable for specific applications. For instance, electromagnetic flow meters are ideal for conductive liquids, while ultrasonic meters are effective for a wide range of fluids with varying viscosities. Data from the International Society of Automation suggests that employing the right type of inline flow meter can enhance measurement precision and reduce waste, leading to potential cost savings of 15% annually for companies in fluid management.

Tips: When choosing an inline flow meter, always consider the fluid characteristics, including viscosity, temperature, and pressure. Ensure that the selected meter meets the required standards for your industry to minimize risks and maximize efficiency. Regular maintenance and calibration are also essential to maintain the accuracy of your flow measurements over time, keeping your operations running smoothly.

Why Choose an Inline Flow Meter for Accurate Fluid Measurement

| Flow Meter Type | Measurement Accuracy | Fluid Compatibility | Installation Type | Typical Applications |

|---|---|---|---|---|

| Electromagnetic Flow Meter | ±0.5% | Water, Wastewater, Slurries | Inline | Municipal Water, Chemical Processing |

| Turbine Flow Meter | ±1% | Oil, Fuels, Water | Inline | Petroleum, HVAC Systems |

| Coriolis Flow Meter | ±0.1% | Liquids and Gases | Inline | Food & Beverage, Pharmaceutical |

| Ultrasonic Flow Meter | ±1% to ±3% | Water, Chemicals | Inline | Water Treatment, Energy |

| Positive Displacement Flow Meter | ±0.5% | High Viscosity Fluids | Inline | Lubricants, Food Products |

Advantages of Inline Flow Meters over Other Measurement Methods

Inline flow meters offer several advantages over traditional measurement methods, primarily due to their ability to provide continuous and accurate readings of fluid flow without disrupting the system. According to a report by the American Society of Mechanical Engineers (ASME), inline flow meters can achieve accuracy levels of up to ±0.5%, significantly enhancing measurement reliability compared to mechanical meters, which often suffer from drift and wear over time. This precision is crucial in industries such as oil and gas, where even minor discrepancies can lead to substantial financial losses.

Furthermore, inline flow meters typically feature a compact design that integrates smoothly into existing piping systems, which minimizes the need for additional installation space. The latest data from the International Society of Automation (ISA) indicates that inline solutions can reduce installation time by up to 30% compared to traditional methods that require separate measurement points. This not only helps in speeding up project timelines but also lowers overall operational costs. Additionally, inline meters are less prone to blockages and maintenance requirements than other technologies, contributing to more efficient, uninterrupted operations.

Key Applications of Inline Flow Meters in Various Industries

Inline flow meters are essential tools across various industries, thanks to their capability to deliver precise fluid measurement. In the oil and gas sector, for instance, the accurate monitoring of hydrocarbons is critical. According to a report by the International Energy Agency, the global oil demand is projected to reach 104.1 million barrels per day by 2026, highlighting the need for reliable measurement systems to enhance operational efficiency and reduce losses during production and transportation.

In the pharmaceutical and food industries, inline flow meters ensure product quality and safety. The Pharmaceutical Research and Manufacturers of America states that more than $62 billion was spent on research and development in 2020. Inline flow meters help maintain stringent standards in the manufacturing process, enabling consistent flow rates and adherence to regulatory requirements. Similarly, in the food industry, precise measurement is vital to meet safety standards and ensure the nutritional content is correctly represented. The Food and Beverage Industry Analysis predicts continued growth, necessitating reliable systems for fluid measurement to keep pace with increasing production demands.

Moreover, inline flow meters are increasingly being adopted in water treatment facilities to monitor and control chemical dosing processes. As reported by the Global Water Market, the worldwide market for water and wastewater treatment is expected to reach $2 trillion by 2025. Accurate flow measurement in these applications not only ensures compliance with environmental regulations but also enhances system efficiency and sustainability. These diverse applications underline the critical role of inline flow meters in achieving accurate fluid measurement across multiple sectors.

Factors to Consider When Choosing an Inline Flow Meter

When selecting an inline flow meter for accurate fluid measurement, several crucial factors need to be taken into consideration. First and foremost is the flow range of the application. According to a report by the American Society of Mechanical Engineers (ASME), accurately measuring flow rates can vary significantly between different systems, with some requiring high precision for low flow rates, while others may be focused on high flow situations. Understanding the specific flow characteristics of the fluid in question, including viscosity and density, plays a critical role in determining the appropriate type of inline flow meter.

Another essential consideration is the compatibility of the flow meter materials with the fluid being measured. A study published in the Journal of Fluid Engineering highlighted that inappropriate material choices could lead to corrosion, affecting the longevity and accuracy of measurements. Furthermore, operational conditions such as temperature and pressure should be assessed to ensure the selected meter can handle expected environmental stresses without compromising performance. Lastly, installation requirements and maintenance procedures must be evaluated, as they can impact the overall efficiency and reliability of fluid measurement. By carefully analyzing these factors, one can ensure the selection of an inline flow meter that provides accurate and reliable readings over time.

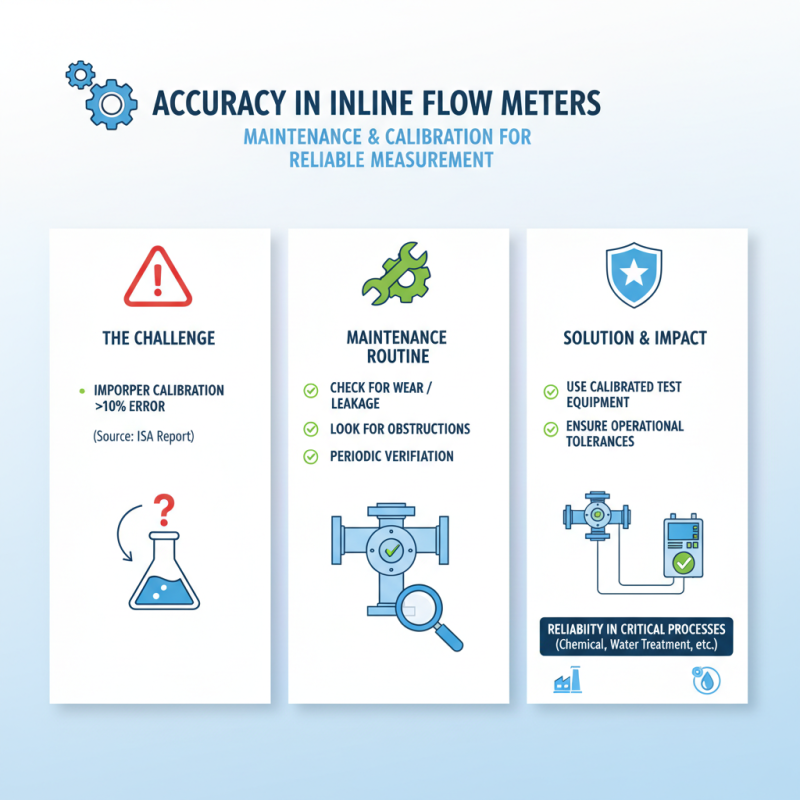

Maintenance and Calibration Tips for Inline Flow Meters

Maintaining the accuracy of inline flow meters requires a structured approach to both maintenance and calibration. According to a report from the International Society of Automation, improper calibration can lead to measurement errors exceeding 10%, which is significant in critical processes such as chemical manufacturing and water treatment. Regular maintenance schedules should include checking for any signs of wear, leakages, or obstructions, as these can adversely affect flow measurement quality. It is recommended that operators utilize calibrated test equipment to periodically verify the accuracy of their flow meters, ensuring that they remain within their specified operational tolerances.

Calibration of inline flow meters should ideally be conducted at least once a year, depending on the application and operational environment. The Flow Measurement and Instrumentation journal indicates that processes involving highly viscous or corrosive fluids might need more frequent calibration due to their potential impact on sensor performance. Additionally, using flow meter calibration aggregates data supports the development of predictive maintenance strategies, which can further enhance measurement reliability and operational efficiency. Integrating these practices ensures consistency in fluid measurement, ultimately contributing to improved process control and reduced costs over time.

Related Posts

-

How to Choose the Right Inline Flow Meter for Your Industrial Applications

-

Top 10 Inline Flow Meters: Key Features, Benefits, and Buying Guide

-

What is a Digital Water Flow Meter and How It Improves Water Management Efficiency

-

Understanding the Mechanisms Behind Turbine Flow Meters

-

Ultimate Guide to Understanding Different Flow Meter Types for Your Business Needs

-

5 Reasons Why the 2 Inch Flow Meter is a Game Changer for Your Industry