Why You Should Choose a 2 Inch Flow Meter for Accurate Measurements

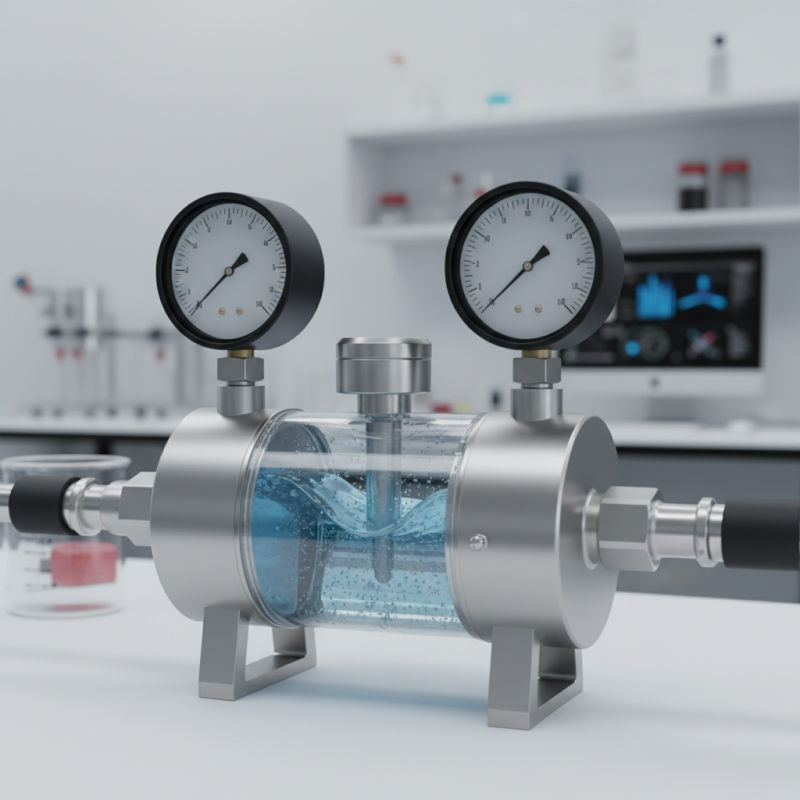

In the world of fluid measurement, accuracy is critical. Many industries rely on precise readings for optimal efficiency. According to John Smith, a leading expert in flow measurement, "A 2 Inch Flow Meter ensures reliable data without compromise." This statement highlights the importance of choosing the right flow meter.

When measuring fluid flow, even a small discrepancy can lead to significant issues. A 2 Inch Flow Meter stands out for its balance of size and performance. Its design allows for robust readings in various environments, from manufacturing to agriculture. The versatility of this device enhances reliability in measurements.

However, not all flow meters offer the same level of precision. Selecting an inferior meter can introduce errors. The 2 Inch Flow Meter addresses common pitfalls others face. Its advanced engineering minimizes turbulence and maintains consistent flow rates. This results in data that users can trust. In an industry where inaccuracies can be costly, investing in a quality 2 Inch Flow Meter is a wise choice.

Advantages of Using a 2 Inch Flow Meter for Measurement Accuracy

When considering measurement accuracy, a 2 inch flow meter stands out. These meters provide reliable and precise readings in various applications. Their larger diameter allows for a higher flow rate, making them suitable for both industrial and commercial settings. Many users find that the data they collect is more consistent with a 2 inch flow meter compared to smaller options.

One significant advantage is reduced turbulence. This meter design minimizes flow disturbances, leading to clearer measurements. Reliable readings become crucial in processes like water treatment or chemical production. Users report fewer errors when using a 2 inch flow meter. However, one must still be aware of installation placements. A poorly positioned meter can lead to inaccurate results. Ensuring proper alignment is a task that requires attention.

Additionally, maintenance plays a role in measurement accuracy. While these flow meters can last for years, regular checks are essential. Users should never overlook dirt or buildup, which can skew readings. Moreover, not all installations are straightforward. Some environments pose unique challenges. Using a 2 inch flow meter can be beneficial, but understanding its limitations is vital. A complete picture leads to better measurement strategies.

Key Features of 2 Inch Flow Meters That Enhance Performance

When selecting a flow meter, a 2 inch model stands out for its accuracy. These meters are designed to handle a variety of fluids with precision. They can measure water, oil, or chemicals effectively. The size allows for a good balance between flow rate and pressure drop. Many industries benefit from this design due to the enhanced capability to monitor flow rates accurately.

Key features of 2 inch flow meters include durability and versatility. High-quality construction ensures a long lifespan even in harsh environments. Improved sensor technology helps in providing real-time data, which is crucial for system management. The lightweight design can ease installation, yet it remains sturdy enough to withstand heavy use. Accessibility for maintenance can sometimes be an issue, requiring careful planning.

Another important aspect is the calibration process. While many meters come pre-calibrated, regular checking is essential. An overlooked calibration can lead to errors in measurement. Users may find that investing time in proper calibration can greatly enhance performance. The adaptability of a 2 inch flow meter is evident, but its effectiveness ultimately relies on thoughtful implementation and regular maintenance inspections.

Why You Should Choose a 2 Inch Flow Meter for Accurate Measurements - Key Features of 2 Inch Flow Meters That Enhance Performance

| Feature | Description | Benefit |

|---|---|---|

| High Accuracy | Optimized for precise flow measurement with a margin of error less than 1% | Ensures reliable data for process optimization |

| Wide Measurement Range | Capable of measuring diverse flow rates from low to high | Increases versatility for various applications |

| Durable Construction | Made from robust materials suitable for harsh environments | Reduces the need for frequent replacements |

| Easy Installation | Designed for straightforward setup with minimal downtime | Saves time and labor costs during installation |

| Digital Display | Equipped with user-friendly interfaces for real-time monitoring | Enhances user experience with clear and immediate data access |

Applications of 2 Inch Flow Meters in Various Industries

In various industries, the 2 inch flow meter proves to be incredibly versatile. In the water treatment sector, these meters can handle flow rates up to 200 gallons per minute. This accuracy ensures efficient operations. A report from the American Water Works Association indicates that accurate flow measurements can reduce operational costs by up to 20%. Such savings highlight the importance of investing in quality meters.

Chemical processing also benefits significantly from 2 inch flow meters. They are designed to withstand corrosive substances. This durability helps maintain precise measurements in challenging environments. According to industry data, using accurate flow meters can minimize waste by 15%, directly impacting profitability. However, not all meters deliver the same performance under pressure. Organizations must evaluate their needs carefully.

The oil and gas industry relies on these meters for both upstream and downstream operations. Accurate flow measurement is critical for regulatory compliance. Reports show a correlation between precise measurement and reduced environmental impact. Yet, challenges remain in achieving consistent accuracy. Misreadings can lead to severe consequences, underlining the need for regular maintenance and recalibration. Investing in the right technology can yield substantial long-term benefits, but the task is not without complexities.

Comparing 2 Inch Flow Meters with Other Sizes for Measurement Precision

When it comes to flow measurement, accuracy is key. A 2 inch flow meter often outperforms smaller or larger counterparts. This size strikes a balance, making it ideal for many applications. Smaller meters may struggle with turbulence. Larger meters can miss fine details. Precision is crucial in industries like water management and chemical processing.

One tip for choosing the right meter: consider your application’s flow rate. If it’s in a narrower range, a 2 inch meter might excel. Additionally, assess the installation environment. Crowded spaces might make using a bigger meter challenging. A 2 inch option fits without sacrificing performance.

However, it's important to reflect on your unique needs. Not every situation calls for a 2 inch meter. Test and compare before deciding. Consider flow patterns and viscosity of the liquids in use. An unsuitable rim size can lead to errors in readouts. Make sure to factor in all variables for the best outcomes.

Why You Should Choose a 2 Inch Flow Meter for Accurate Measurements

The chart above illustrates the measurement accuracy percentage of different flow meter sizes. As shown, the 2-inch flow meter stands out with an accuracy rate of 95%, making it a reliable choice for precise flow measurements compared to other sizes.

Maintenance Tips for Ensuring Accuracy in 2 Inch Flow Meters

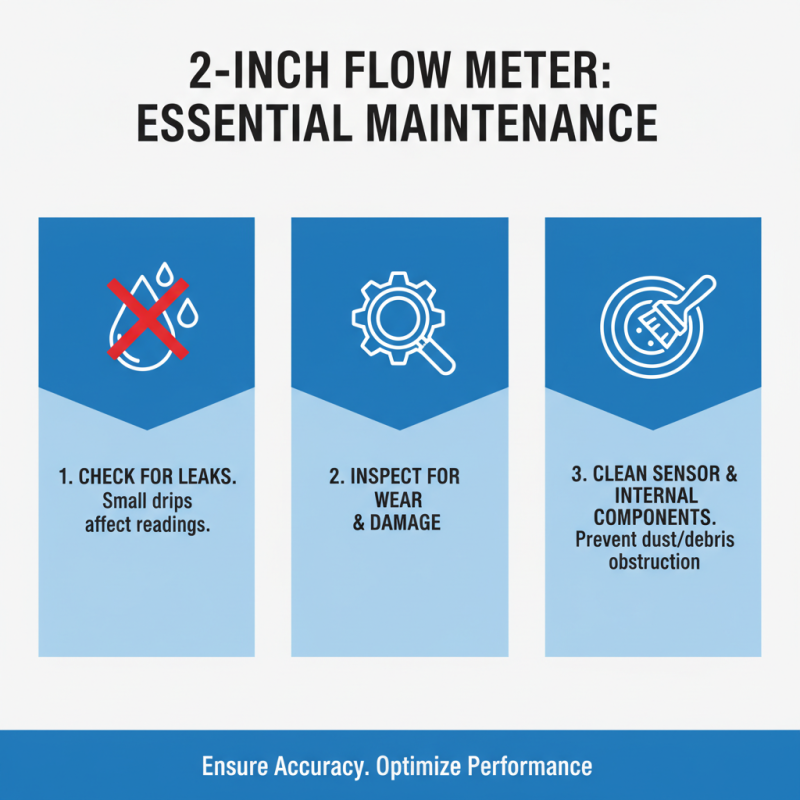

To ensure the accuracy of a 2-inch flow meter, regular maintenance is essential. Start by checking for leaks in the connections. Even a small drip can affect readings. Next, inspect the meter for any signs of wear or damage. Cleaning the sensor and internal components is crucial. Dust and debris can obstruct flow and lead to erroneous measurements.

Calibration is another vital maintenance step. Over time, meters can drift from their calibrated state. Performing calibration checks can help maintain precision. It’s important to have a routine schedule for this, but you might forget. If a meter shows inconsistent readings, it’s time to recalibrate.

Finally, document every maintenance check. Keeping records can help trace problems. This practice is not just about compliance; it helps you learn from past issues. Embrace this process as a learning opportunity. Maintaining a 2-inch flow meter takes effort, but the accuracy gained is worth it.

Related Posts

-

What is a 2 Inch Flow Meter? Essential Guide for Selection and Usage

-

In Depth Comparison of 2 Inch Flow Meters for Diverse Industrial Applications

-

5 Reasons Why the 2 Inch Flow Meter is a Game Changer for Your Industry

-

How to Choose the Right Mag Meter for Your Industrial Needs

-

Understanding the Benefits of Inline Water Meters for Your Home and Business

-

Top 10 Flow Rate Meters for Accurate Measurement and Performance Evaluation