Best Water Flow Sensor for Accurate Measurement?

In the realm of fluid dynamics, precise measurement is paramount. The effectiveness of a Water Flow Sensor impacts many industries, including agriculture and water management. As Dr. Emily Carter, a leading expert in hydraulic engineering, states, “Accurate flow measurement is the backbone of water resource management.”

Selecting the best Water Flow Sensor can be challenging. Many sensors offer different technologies, each with unique advantages and flaws. Some may overmeasure or underestimate flow rates, leading to critical errors in applications. Practical usage and data validation remain essential.

Moreover, recalibration and maintenance are often overlooked. Not all Water Flow Sensors can adapt to changing conditions effectively. Industry professionals frequently face difficulties when relying on subpar tools. It’s crucial to assess both accuracy and reliability regularly. A thoughtful approach can ensure efficient water management and sustainable practices.

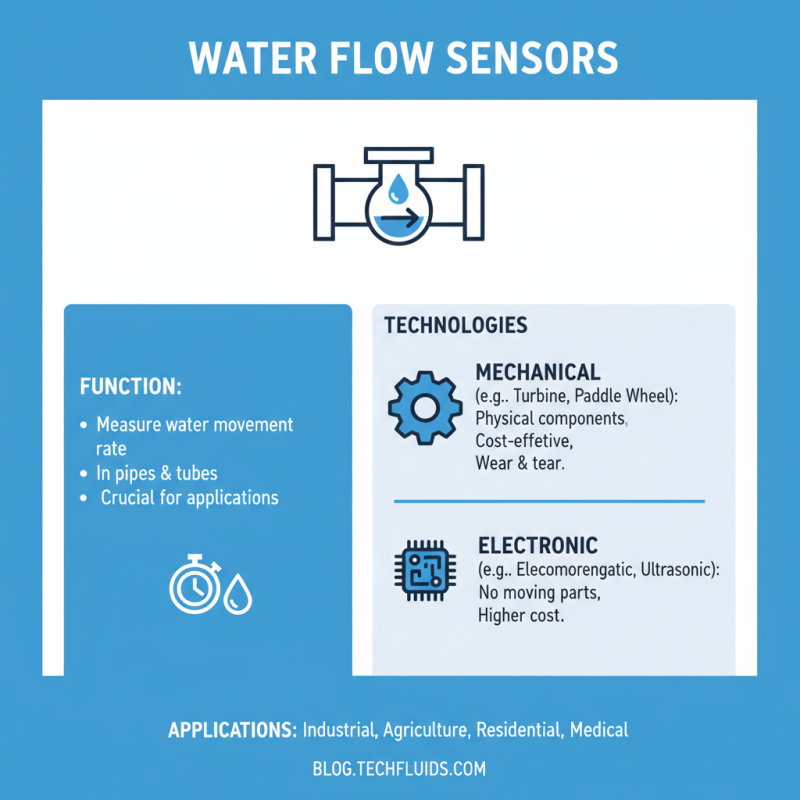

Understanding Water Flow Sensors: An Overview of Technologies

Water flow sensors are crucial for various applications. They measure the rate of water movement in pipes. Different technologies are available, each offering unique benefits and limitations. Some sensors use mechanical components, while others rely on electronic methods.

Mechanical flow sensors often include paddle wheels. They rotate based on water flow. This design can be simple and cost-effective but may struggle with accuracy at low flow rates. Electronic sensors, on the other hand, could utilize ultrasonic or electromagnetic principles. These can provide precise measurements but may be more expensive and complex.

Many users face challenges choosing the right sensor. Factors such as pipe size, expected flow rates, and installation environment play a role. Reflecting on these details helps in making an informed decision. It’s essential to ensure compatibility with existing systems. A miscalculation may lead to poor performance or maintenance issues later on.

Key Features to Consider When Choosing a Water Flow Sensor

When selecting a water flow sensor, accuracy is paramount. Many sensors feature varying technologies. For instance, electromagnetic sensors are known for high precision. They measure flow velocity using electromagnetic fields. Research indicates that these sensors can achieve an accuracy of ±0.5% in optimal conditions. However, factors like fluid viscosity may affect performance.

Another crucial aspect is the sensor’s response time. Quick response ensures real-time monitoring. Some sensors deliver data every second, while others may take several seconds. This delay can lead to inaccuracies in rapidly changing conditions. According to a recent industry report, over 30% of sensor failures are linked to insufficient response times. Choosing a model with a short reaction time is essential for reliable readings.

Durability also must be considered. A sensor’s lifespan can vary based on the material used and the environment it operates in. For instance, corrosive environments can shorten a sensor's life. Regular maintenance may extend lifespan but can be time-consuming. In fact, nearly 25% of users reported premature sensor failure due to neglect. Therefore, balancing durability, maintenance, and measurement accuracy is a challenge many face in sensor selection.

Comparative Analysis of Leading Water Flow Sensor Brands

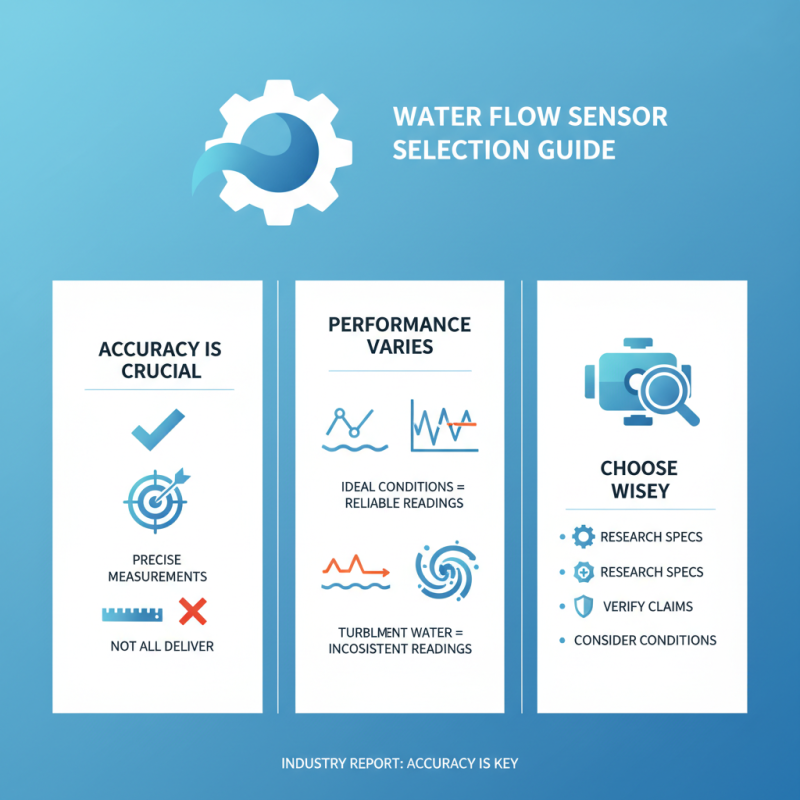

When selecting a water flow sensor, various options are available in the market. A recent industry report indicates that accuracy is crucial. Many sensors claim precise measurements, but not all deliver. The performance of these devices can vary significantly under different conditions. For instance, some sensors struggle in turbulent water, leading to inconsistent readings.

Moreover, compatibility with existing systems is another concern. Many users face challenges when integrating new sensors with old setups. This can lead to additional costs and installation complexities. According to research, nearly 30% of water flow sensor installations face compatibility issues. It's essential to consider these factors when evaluating top brands.

Size and maintenance also come into play. Some sensors require frequent upkeep, which can be a burden. Other models are more user-friendly and need less maintenance, making them more attractive. However, this often reflects in their price. Balancing cost, accuracy, and ease of use is no small feat for users.

Installation and Maintenance Tips for Optimal Sensor Performance

When selecting a water flow sensor, proper installation and maintenance are crucial for effective performance. According to industry reports, systems that regularly undergo maintenance can increase accuracy by up to 25%. Therefore, ensure that the sensor is securely fitted and free from obstructions which may skew readings. Place the device in a straight section of piping, avoiding bends or fittings nearby.

Regular cleaning is essential. Sediment buildup can obstruct flow, leading to inaccurate measurements. Use a soft cloth and appropriate cleaning solution for upkeep. It might seem simple, but minor omissions can lead to substantial errors in data collection. Be sure to check for leaks regularly; even small leaks can impact accuracy.

Usage patterns should be documented. If flow rates vary significantly, recalibration may be necessary. Many users forget this critical step. Remember, failure to recalibrate may produce misleading results. After all, data integrity is paramount in any measurement system.

Best Water Flow Sensor for Accurate Measurement? - Installation and Maintenance Tips for Optimal Sensor Performance

| Sensor Type | Measurement Range (L/min) | Accuracy (%) | Power Supply (V) | Installation Method | Maintenance Tips |

|---|---|---|---|---|---|

| Ultrasonic Sensor | 0.5 - 50 | ±2% | 12 - 24 | Clamped on pipe | Clean transducer regularly |

| Electromagnetic Sensor | 1 - 100 | ±1% | 24 - 240 | In-line installation | Inspect wiring connections |

| Mechanical Impeller | 0.1 - 200 | ±5% | 5 - 15 | Inline or valve installation | Lubricate bearings periodically |

| Vortex Flow Sensor | 0.2 - 150 | ±3% | 12 - 36 | In-line pipeline | Check for blockages |

Applications of Water Flow Sensors in Various Industries

Water flow sensors play a crucial role in various industries. In agriculture, they help monitor irrigation systems. Accurate water measurement ensures proper crop growth. According to recent studies, efficient irrigation can increase crop yields by up to 30%. This highlights the importance of precise flow sensors in optimizing water usage.

In the manufacturing sector, water flow sensors are vital for production efficiency. They help in managing water consumption rates. Industries that implement these sensors often achieve a reduction in water waste by about 20%. This not only decreases costs but also supports sustainability efforts. However, the integration can be challenging. Companies may face issues with sensor calibration or system compatibility.

The HVAC industry also benefits from water flow sensors. They monitor cooling systems and help maintain temperature control. This is crucial in large buildings where energy efficiency is a priority. Yet, technicians sometimes overlook maintenance. Regular checks are necessary to ensure accurate readings. Inaccurate data can lead to system inefficiencies and unnecessary energy consumption.

Related Posts

-

Understanding How Flow Transmitters Revolutionize Industrial Fluid Management

-

Innovative Alternatives to Inline Flow Meter Solutions for Enhanced Measurement Accuracy

-

Innovative Solutions for Inline Water Meter Efficiency Optimization

-

7 Expert Tips for Selecting the Best Mag Meter for Your Industry

-

How to Effectively Choose the Right Hydraulic Flow Meter for Your Industrial Needs

-

Understanding Flow Transmitters: The Key to Accurate Fluid Measurement in Industrial Applications