10 Best Electromagnetic Flow Meters for Accurate Fluid Measurement

In the realm of fluid measurement, accuracy is paramount, and one of the most reliable technologies available is the Electromagnetic Flow Meter. According to Dr. Emily Carter, a leading expert in flow measurement technology, "The precision of an Electromagnetic Flow Meter is unmatched when it comes to non-conductive fluids, making it indispensable for various industrial applications." This assertion underscores the significance of selecting the right flow measurement device, particularly in industries that require meticulous monitoring of fluid dynamics.

Electromagnetic Flow Meters utilize the principles of electromagnetism to provide accurate and consistent readings, regardless of changes in fluid density or viscosity. Their ability to measure volumetric flow rates without any moving parts aligns with modern standards for efficiency and reliability. As industries continue to evolve, the demand for precise measurement solutions only intensifies, making the exploration of the best Electromagnetic Flow Meters a vital topic for engineers and technicians alike.

In this article, we will delve into the top 10 Electromagnetic Flow Meters that stand out for their performance, durability, and versatility. Whether in the water treatment sector, chemical processing, or food and beverage applications, understanding the capabilities of these flow meters will empower professionals to make informed decisions that enhance operational efficiency and product integrity.

Overview of Electromagnetic Flow Meters and Their Applications

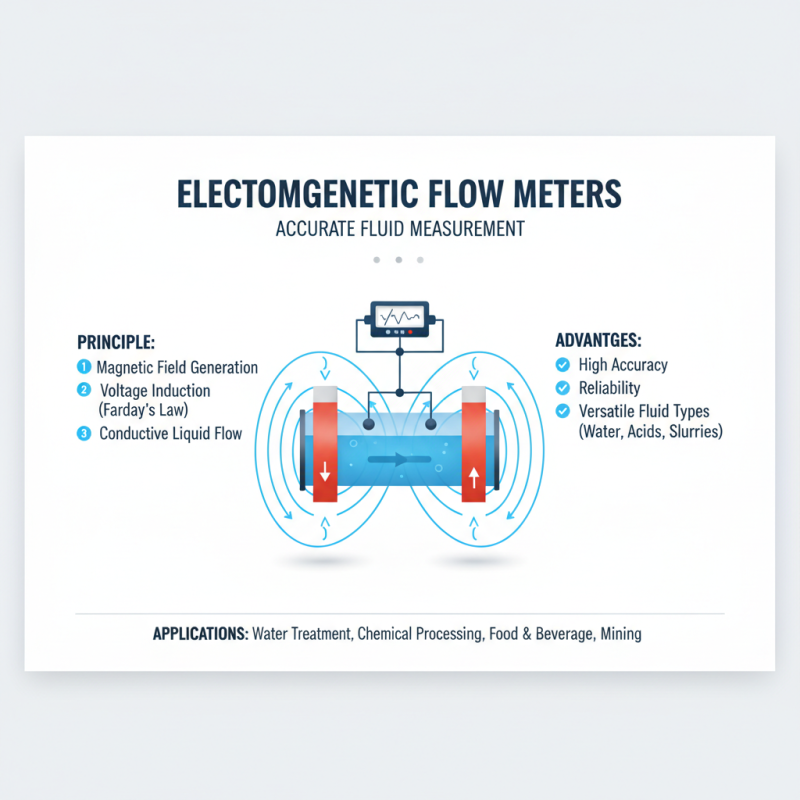

Electromagnetic flow meters are essential devices that utilize the principles of electromagnetic induction to measure the flow of conductive fluids accurately. These flow meters operate by generating a magnetic field and measuring the voltage induced when a conductive liquid passes through the field. This method provides several advantages, including high accuracy, reliability, and the ability to measure a broad range of flow rates and fluid types, making them suitable for diverse applications.

In various industries, electromagnetic flow meters play a crucial role. They are commonly used in water treatment facilities, chemical processing plants, and food and beverage industries. Their non-invasive nature allows for minimal disturbance to the fluid flow, which is particularly beneficial in processes where maintaining fluid integrity is vital. Additionally, these devices can measure fluids with varying viscosities and flow conditions, making them ideal for applications that involve slurries or waste materials. As industries increasingly focus on automation and precision, the adoption of electromagnetic flow meters continues to grow, demonstrating their significance in modern fluid measurement technology.

Key Features to Consider When Choosing an Electromagnetic Flow Meter

When selecting an electromagnetic flow meter, several key features must be taken into consideration to ensure accurate fluid measurement. Firstly, it is crucial to assess the meter's operating range, including the flow rate and the size of the pipe it will be installed in. Ensuring compatibility with the specific fluid characteristics, such as temperature, viscosity, and conductivity, can significantly impact measurement accuracy and overall performance.

Another vital aspect to consider is the type of materials used in the construction of the flow meter. The inner lining and electrode materials should be resistant to corrosion and wear, especially when dealing with harsh or abrasive fluids. Additionally, the availability of calibration options and the ability to easily integrate the device with existing systems for data collection or remote monitoring are important for maintaining precision in various applications. Overall, selecting the right electromagnetic flow meter requires careful analysis of these features to meet specific operational needs effectively.

Fluid Measurement Accuracy of Electromagnetic Flow Meters

Top 10 Electromagnetic Flow Meters for Precise Fluid Measurement

Electromagnetic flow meters are vital tools in various industries, providing precise measurements of conductive liquids. The underlying technology operates on Faraday's Law of electromagnetic induction, which allows for accurate flow measurement regardless of changes in viscosity or density. According to a report by the Global Electromagnetic Flow Meter Market, the sector is projected to reach a value of approximately $1.5 billion by 2026, highlighting the growing need for reliable fluid measurement solutions across sectors such as water treatment, chemical processing, and food and beverage manufacturing.

Accuracy is paramount in fluid measurement, and electromagnetic flow meters excel in this regard. Research indicates that these devices can achieve an accuracy level of up to ±0.5%, making them ideal for applications where precision is crucial. Furthermore, they offer significant advantages such as low maintenance requirements and resistance to wear, since there are no moving parts. As industries increasingly seek automation and efficiency in their processes, the demand for high-quality electromagnetic flow meters continues to rise, underpinning their role as a cornerstone in modern fluid management practices.

Comparison of Technical Specifications and Performance Metrics

When evaluating electromagnetic flow meters, technical specifications and performance metrics play a crucial role in determining their suitability for various applications. Key specifications to consider include the meter's size, flow range, and operating pressure, as these factors directly influence the accuracy and reliability of fluid measurement. Additionally, the materials used in construction can affect the meter's durability and compatibility with different fluids, especially when dealing with corrosive substances. Advanced features such as temperature compensation, signal processing technology, and calibration methods can also be pivotal in enhancing measurement precision.

Performance metrics such as accuracy, repeatability, and response time are vital in assessing the operational efficiency of electromagnetic flow meters. Accuracy is typically expressed as a percentage of the flow rate and reflects how closely the meter's readings align with the actual flow. Repeatability indicates the consistency of measurements under identical conditions, which is essential for applications requiring stable and reliable data. Response time, representing the speed at which the meter can react to changes in flow, is crucial in dynamic environments where fluid flow may vary rapidly. By comparing these technical specifications and performance metrics, users can make informed decisions about which electromagnetic flow meters best meet their specific requirements.

10 Best Electromagnetic Flow Meters for Accurate Fluid Measurement - Comparison of Technical Specifications and Performance Metrics

| Model | Flow Range (m³/h) | Accuracy (%) | Fluid Temperature (°C) | Connection Size (mm) | Power Supply (V) | Communication Protocol |

|---|---|---|---|---|---|---|

| Model A | 0.5 - 150 | ±0.5 | -20 to 80 | 25 | 24 | Modbus |

| Model B | 1 - 200 | ±0.2 | 0 to 90 | 50 | 220 | Profibus |

| Model C | 0.1 - 100 | ±1.0 | -10 to 70 | 15 | 12 | Analog |

| Model D | 5 - 500 | ±0.3 | -20 to 60 | 32 | 110 | HART |

| Model E | 0.3 - 300 | ±0.5 | -10 to 80 | 40 | 24 | Ethernet |

| Model F | 0.5 - 150 | ±0.04 | -20 to 90 | 25 | 230 | Canbus |

| Model G | 1 - 400 | ±0.6 | 0 to 95 | 50 | 220 | RS485 |

| Model H | 0.2 - 200 | ±0.5 | -15 to 85 | 20 | 24 | Wireless |

| Model I | 0.5 - 100 | ±0.3 | -10 to 70 | 25 | 120 | Modbus TCP |

| Model J | 0.1 - 150 | ±0.5 | -20 to 80 | 15 | 220 | Analog |

Maintenance and Calibration Tips for Electromagnetic Flow Meters

Maintaining the accuracy and reliability of electromagnetic flow meters hinges on regular maintenance and proper calibration. One of the most critical aspects of maintaining these devices is ensuring that the electrodes remain clean and free from buildup. Regular inspection should be performed to check for any obstructions or deposits that may affect performance. Cleaning protocols can vary depending on the type of fluid being measured; however, using appropriate cleaning solutions that will not damage the electrodes is essential. Additionally, an inspection of the flow meter's housing and wiring should be routine to avoid any electrical issues that could disrupt functionality.

Calibration is another essential component for accurate fluid measurement. Flow meters should be calibrated periodically, and the frequency of calibration can depend on factors such as operational conditions and the type of fluids being measured. It is important to follow manufacturer guidelines for calibration procedures, which often involve comparing the flow meter's readings against a known standard or reference. Any discrepancies should be noted, and adjustments made accordingly to ensure optimal performance. Furthermore, maintaining thorough documentation during maintenance and calibration can provide valuable insights into the meter's performance over time, helping to identify patterns that may indicate when additional servicing is required.

Related Posts

-

Understanding the Benefits of Electromagnetic Flow Meters in Industrial Applications

-

How to Choose the Right Electromagnetic Flow Meter for Your Application

-

7 Best Flow Meter Types for Accurate Measurement in 2023

-

Ultimate Guide to Understanding Irrigation Flow Meters: Key Insights from Industry Experts and Data

-

Ultimate Guide to Understanding Different Flow Meter Types for Your Business Needs

-

How to Effectively Choose the Right Air Flow Meter for Your Industrial Needs