Understanding the Benefits of Turbine Meters in Modern Industry Applications

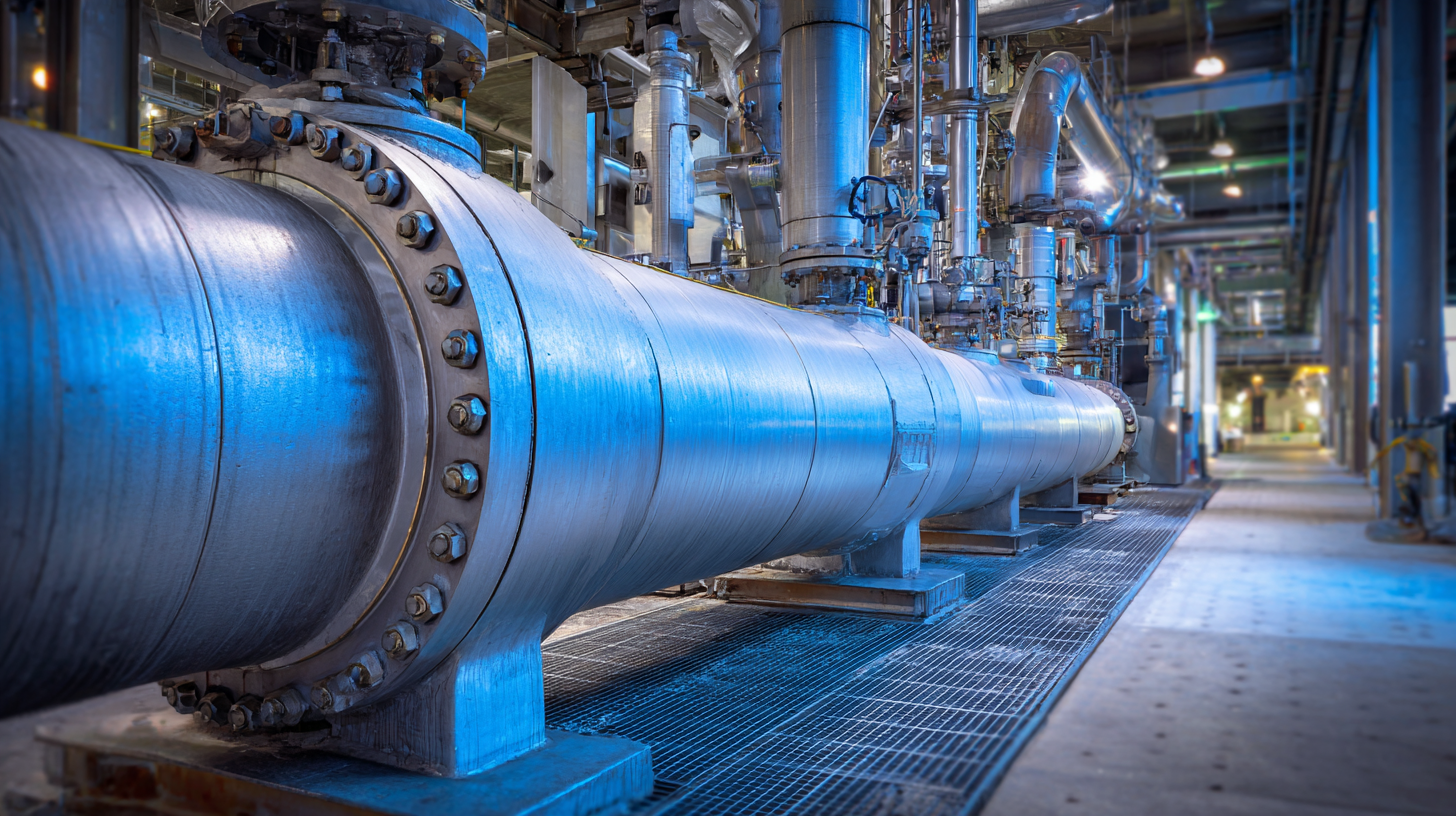

In today's rapidly advancing industrial landscape, efficient measurement and control of fluid flow are paramount for optimizing operations and minimizing costs. One such innovative solution making waves in various applications is the Turbine Meter. Renowned for their precision and reliability, Turbine Meters utilize the rotational movement of a turbine within the fluid stream to accurately gauge flow rates. This technology is especially beneficial in industries ranging from petrochemicals to wastewater management, where the need for precise measurement and reporting is critical. By understanding the inherent advantages of Turbine Meters—including their high accuracy, wide range of measurable flow rates, and suitability for both liquids and gases—industries can implement more effective monitoring systems. This article aims to delve into the myriad benefits offered by Turbine Meters and provide practical tips for their integration into modern industrial applications.

Understanding the Basics of Turbine Meters and Their Functionality

Turbine meters are widely recognized for their efficiency and accuracy in measuring fluid flow in various industrial applications. These devices operate on a straightforward principle: when fluid passes through the meter, it spins a turbine wheel positioned in the flow path. The speed of the wheel’s rotation is directly proportional to the flow rate of the fluid. This relationship allows for precise measurements, making turbine meters essential for industries that rely on accurate flow data, such as oil and gas, water treatment, and pharmaceuticals.

The functionality of turbine meters extends beyond mere measurement. They are designed to handle a range of fluid types and conditions, including high flow rates and various viscosities. The choice of materials for the turbine and housing ensures durability and corrosion resistance, which is crucial in harsh environments.

Moreover, turbine meters can be integrated with advanced digital readouts and data logging systems, enabling real-time monitoring and analysis. This combination of accuracy, durability, and the ability to interface with modern technology underscores the pivotal role turbine meters play in enhancing operational efficiency and safety in contemporary industrial settings.

Identifying Key Industries That Benefit from Turbine Meter Technology

Turbine meters have become an essential technology across various industries, providing accurate and reliable flow measurement. Key industries benefiting from turbine meter technology include the water and wastewater management, oil and gas, and manufacturing sectors. In water management, turbine meters ensure precise measurement of flow rates, aiding in efficient resource allocation and leak detection. Similarly, in the oil and gas sector, these meters are crucial for measuring the flow of liquids and gases, helping in processing and production optimization.

Turbine meters have become an essential technology across various industries, providing accurate and reliable flow measurement. Key industries benefiting from turbine meter technology include the water and wastewater management, oil and gas, and manufacturing sectors. In water management, turbine meters ensure precise measurement of flow rates, aiding in efficient resource allocation and leak detection. Similarly, in the oil and gas sector, these meters are crucial for measuring the flow of liquids and gases, helping in processing and production optimization.

Tips: When selecting a turbine meter for your industry, consider factors such as the specific fluids being measured, operating conditions, and maintenance requirements. Investing in a high-quality turbine meter can significantly enhance operational efficiency and reduce long-term costs.

Moreover, as industries increasingly focus on sustainability, turbine meters play a critical role in monitoring and managing resources effectively. They help organizations comply with regulations, reduce waste, and promote responsible consumption. This alignment with environmental goals makes turbine meters a vital component in modern industry applications.

Tips: Regular maintenance checks and calibration of turbine meters can enhance their accuracy and longevity. Implementing best practices in meter installation can further optimize performance and prevent measurement discrepancies.

Examining the Advantages of Turbine Meters for Accurate Flow Measurement

Turbine meters have emerged as a favored choice in various industrial applications, primarily due to their remarkable accuracy in measuring flow rates. These meters utilize a series of blades that rotate as fluid passes through them, translating the kinetic energy of the flow into measurable rotational speed. This conversion process provides precise flow measurements that are essential for industries where accuracy is paramount, including oil and gas, water treatment, and chemical manufacturing.

One of the standout advantages of turbine meters is their ability to maintain high accuracy across a wide range of flow rates. This versatility allows industries to use them in diverse operational conditions without sacrificing performance. Furthermore, turbine meters are generally compact, leading to easier installation and integration into existing systems. Additionally, their low-pressure drop characteristic minimizes energy loss, contributing to more efficient operations. Overall, the precision and adaptability of turbine meters make them a valuable asset for modern industry applications, ensuring that businesses can rely on accurate flow measurements for optimal performance.

Understanding the Benefits of Turbine Meters in Modern Industry Applications

Best Practices for Installing and Maintaining Turbine Meters in Industrial Settings

Turbine meters have emerged as a pivotal component in various industrial applications, owing to their accuracy and efficiency in measuring fluid flow. However, the effectiveness of these meters largely hinges on proper installation and maintenance practices. According to a report by the International Society for Measurement and Control, improper installation can lead to measurement inaccuracies of up to 15%, which can significantly impact operational efficiency. It is vital to ensure that turbine meters are installed in straight pipe sections to minimize turbulence, which can distort readings.

Maintenance is equally critical in ensuring the longevity and accuracy of turbine meters. A survey conducted by the American Society of Mechanical Engineers indicated that routine maintenance can improve meter accuracy by approximately 10% and extend operational life by 30%. Industry best practices recommend regular calibration checks and periodic inspections to identify wear and tear. Utilizing specialized tools for maintaining turbine meters can further enhance their reliability, ultimately contributing to improved process control and reduced operating costs in modern industrial settings. Implementing these practices not only maximizes the investment in metering technologies but also aligns with the industry's push for enhanced operational integrity and efficiency.

Understanding the Benefits of Turbine Meters in Modern Industry Applications

| Application Area | Key Benefits | Best Practices for Installation | Maintenance Tips |

|---|---|---|---|

| Oil and Gas | High accuracy, long lifespan | Ensure proper alignment and minimize turbulence | Regular calibration and check for wear |

| Water Treatment | Precise flow measurement, low pressure drop | Install in straight sections of piping | Inspect for blockages and clean regularly |

| Chemical Processing | Resistant to corrosive materials, durable | Use compatible materials for installation | Monitor seals and joints for leaks |

| Food and Beverage | Sanitary options available, accurate measurement | Follow hygiene regulations during installation | Clean frequently to avoid contamination |

Comparing Turbine Meters with Other Flow Measurement Technologies

Turbine meters have gained popularity in industrial applications due to their accuracy and efficiency in flow measurement. When comparing turbine meters to other flow measurement technologies, such as positive displacement meters and electromagnetic meters, several key differences emerge. While positive displacement meters are known for their high accuracy in low-flow conditions, turbine meters excel in high-flow scenarios, where they provide a more consistent and reliable measurement.

Additionally, electromagnetic meters offer advantages in measuring conductive fluids without any moving parts, making them ideal for certain applications. However, turbine meters stand out with their simplicity, lower cost, and ease of maintenance. Unlike electromagnetic meters, which can be influenced by changes in conductivity, turbine meters maintain accuracy across a broader spectrum of fluid types. Their mechanical nature allows for straightforward installation and operation, making them suitable for various industries, from water treatment to oil and gas, where accurate flow measurement is crucial for operational efficiency.

Related Posts

-

How to Select the Best Turbine Meter for Your Industrial Needs

-

Understanding Common Challenges with Magnetic Flow Meters for Global Buyers

-

Innovative Alternatives to Inline Flow Meter Solutions for Enhanced Measurement Accuracy

-

Understanding the Mechanisms Behind Turbine Flow Meters

-

How to Choose the Right Mag Meter for Your Industrial Needs

-

Innovative Solutions for Magnetic Flow Meter Applications Showcased at 2025 China Import and Export Fair