Understanding the Benefits of Electromagnetic Flow Meters in Industrial Applications

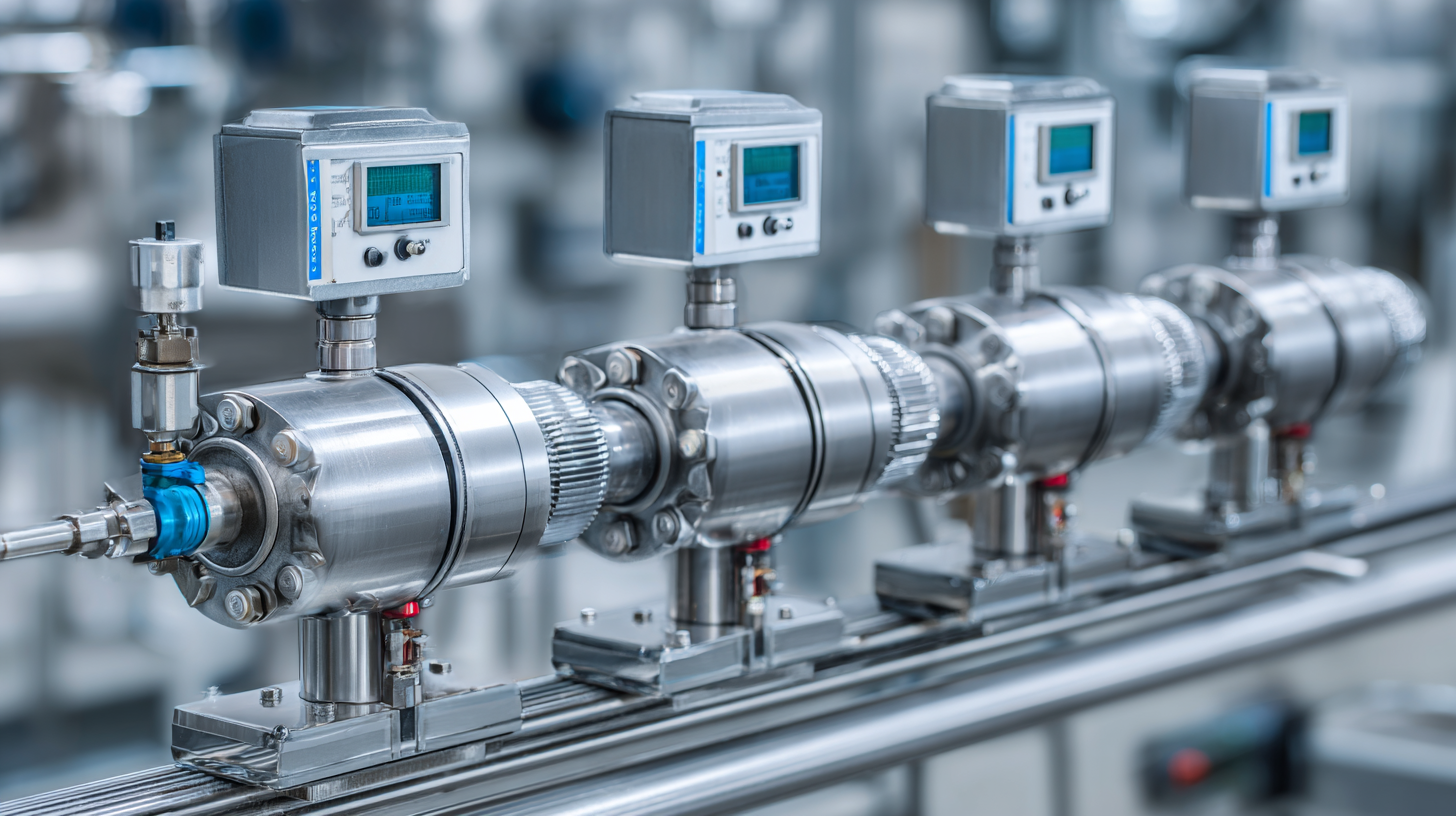

In today's rapidly evolving industrial landscape, the adoption of advanced measurement technologies is crucial for enhancing operational efficiency and ensuring accurate data collection. One such technology, the Electromagnetic Flow Meter, has gained prominence across various sectors due to its ability to provide precise flow measurement of conductive liquids without mechanical components.

According to a recent market analysis by Research and Markets, the global electromagnetic flow meter market is expected to grow at a CAGR of 6.2% from 2022 to 2027, driven by increasing demand in wastewater management, food and beverage, and chemical industries. These flow meters not only reduce maintenance costs but also improve energy efficiency, making them an essential tool for industries striving for sustainability.

According to a recent market analysis by Research and Markets, the global electromagnetic flow meter market is expected to grow at a CAGR of 6.2% from 2022 to 2027, driven by increasing demand in wastewater management, food and beverage, and chemical industries. These flow meters not only reduce maintenance costs but also improve energy efficiency, making them an essential tool for industries striving for sustainability.

Understanding the benefits of these meters is key for industries looking to optimize their processes and harness the power of real-time data for better decision-making.

Choosing the Right Electromagnetic Flow Meter for Your Industry Needs

When selecting the right electromagnetic flow meter for your industry needs, it is crucial to consider several factors that align with your operational requirements. According to a recent report by Research and Markets, the global electromagnetic flow meter market is projected to reach approximately $4 billion by 2025, underlining the growing reliance on these instruments across various sectors. The accuracy and reliability of electromagnetic flow meters make them particularly valuable in industries such as water treatment, food and beverage, and pharmaceuticals, where precision is essential for maintaining quality and compliance.

Different industries may require specific features in their flow meters. For instance, in the chemical sector, resistance to aggressive fluids dictates the choice of materials, often necessitating models crafted from durable, corrosion-resistant substances. Additionally, features such as integrated data logging and compatibility with control systems can enhance process monitoring and facilitate regulatory reporting. A survey from the American Society of Mechanical Engineers (ASME) indicated that 75% of industry professionals emphasize the importance of choosing a flow meter that can precisely handle the unique characteristics of their fluids. Understanding these nuances is critical for ensuring optimal performance and longevity of electromagnetic flow meters in your operations.

Key Advantages of Electromagnetic Flow Meters Over Traditional Flow Measurement Methods

Electromagnetic flow meters have gained significant traction in industrial applications due to their superior advantages over traditional flow measurement methods. One of the most noteworthy benefits is their ability to measure the flow of conductive liquids with high accuracy, which is evidenced by a report from the International Society of Automation (ISA) indicating that electromagnetic flow meters can achieve measurement accuracy within ±0.5% of the reading. This level of precision is crucial for industries where maintaining consistent flow rates can impact product quality and operational efficiency.

Moreover, electromagnetic flow meters exhibit exceptional versatility and low maintenance needs, making them a cost-effective solution in the long run. Unlike mechanical flow meters, which can be prone to wear and tear, electromagnetic flow meters have no moving parts. According to a study by MarketsandMarkets, the global electromagnetic flow meter market is projected to grow from $1.6 billion in 2021 to $2.1 billion by 2026, demonstrating their increasing preference in sectors such as water treatment, chemicals, and food and beverage. This growth highlights the significant shift towards advanced flow measurement technologies, revealing that industries are capitalizing on the reliability and efficiency provided by electromagnetic flow meters.

Understanding the Benefits of Electromagnetic Flow Meters in Industrial Applications

This chart illustrates the key advantages of electromagnetic flow meters over traditional flow measurement methods, highlighting their superior accuracy, cost-effectiveness, lower maintenance needs, ease of installation, and wider range of measurement capabilities.

Maintenance Tips for Ensuring Optimal Performance of Electromagnetic Flow Meters

Electromagnetic flow meters are becoming essential in various industrial applications due to their high precision in measuring electrically conductive liquids. To ensure optimal performance, regular maintenance is crucial. Operators should routinely calibrate the flow meters to maintain accurate measurements, especially in environments subject to fluctuating temperatures and pressures.

Additionally, cleaning the electrodes is vital as any buildup can lead to erroneous readings, so implementing a cleaning schedule based on the flow meter's installation environment is recommended.

Another important aspect of maintenance is monitoring the power supply and connections. Any interruptions or fluctuations in the power source can affect the performance of electromagnetic flow meters. Implementing protective measures against power surges and ensuring connections are secure will enhance longevity and reliability.

Finally, operators should be aware of the flow meter's operating limits and ensure that the flow conditions, such as the presence of gas bubbles or solid particles, are within acceptable ranges to prevent potential damage and maintain accuracy in flow measurements.

Implementing Electromagnetic Flow Meters: Best Practices for Successful Integration

When implementing electromagnetic flow meters in industrial applications, adhering to best practices is crucial for optimizing their performance and ensuring accurate measurements. First and foremost, proper installation is key. This involves selecting the appropriate meter size, aligning it correctly within the piping system, and ensuring that there are adequate straight pipe lengths upstream and downstream to minimize turbulence. Following manufacturer guidelines during installation can significantly improve measurement reliability.

Furthermore, regular maintenance is vital to ensure the longevity and accuracy of electromagnetic flow meters. This includes routine checks for calibration, as well as inspecting the electrical connections and the flow sensor for any blockages or wear. Training personnel to understand the operational parameters and monitoring data trends can also enhance the effective use of these devices. By fostering a thorough understanding of both installation and maintenance, industrial facilities can reap the full benefits of electromagnetic flow meters, leading to improved efficiency and reduced operational costs.

| Application Area | Key Benefits | Best Practices for Integration | Challenges |

|---|---|---|---|

| Water Treatment | High accuracy, minimal maintenance | Calibrate before installation, regular checks | Electromagnetic interference |

| Food and Beverage | Hygienic design, non-intrusive measurements | Ensure compliance with food safety standards | Product residue in lines |

| Chemical Processing | Corrosion resistance, capability to handle viscous fluids | Use proper materials for corrosive substances | Installation complexity |

| Mining | Durability in harsh conditions | Protect sensors from dust and debris | Extremes in temperature and pressure |

Understanding Calibration and Accuracy in Electromagnetic Flow Meter Usage

Electromagnetic flow meters (EMFs) are renowned for their ability to measure the flow of conductive fluids with exceptional accuracy. However, the effectiveness of these devices largely depends on proper calibration and understanding their operational parameters. A recent report by the International Society for Measurement and Control indicates that accurate calibration can enhance flow meter performance by up to 20%, significantly reducing measurement uncertainty in industrial applications. This is particularly critical in sectors such as water treatment and chemical processing, where even minor deviations can lead to considerable economic implications.

Calibration of electromagnetic flow meters involves setting their zero point and ensuring that the readings align with known standards. According to a study by the American Society of Mechanical Engineers, routine calibration practices can improve measurement accuracy to ±0.5% of full scale, which is essential for maintaining regulatory compliance and optimizing process efficiency. Additionally, the lifespan of electromagnetic flow meters can be extended significantly through regular maintenance, further enhancing their return on investment for industries relying on precise fluid measurements. Such diligence in calibration and maintenance underscores the importance of these instruments in achieving operational excellence.

Related Posts

-

Understanding Common Challenges with Magnetic Flow Meters for Global Buyers

-

Innovative Alternatives to Inline Flow Meter Solutions for Enhanced Measurement Accuracy

-

How to Select the Best Turbine Meter for Your Industrial Needs

-

How to Choose the Right Mag Meter for Your Industrial Needs

-

How to Choose the Right Electromagnetic Flow Meter for Your Application

-

Innovative Solutions for Magnetic Flow Meter Applications Showcased at 2025 China Import and Export Fair