2025 Guide: How to Choose the Right Flow Transmitter for Your Needs

Selecting the right flow transmitter is critical for optimizing performance and ensuring the accuracy of flow measurement in various industrial applications. As John Smith, a renowned expert in flow measurement technology, aptly states, "The key to an efficient flow measurement system lies in choosing the right flow transmitter tailored to specific operational needs." This insight encapsulates the importance of aligning the functionalities of flow transmitters with the unique demands of processes, whether in water treatment, chemical processing, or HVAC systems.

In 2025, with advancements in technology and an increasing range of options available in the market, making an informed decision is more challenging yet critical than ever. Flow transmitters come in various designs and capabilities, each offering distinct advantages that cater to specific fluid types, flow conditions, and environmental factors. Understanding these nuances is essential for professionals aiming to enhance system efficiency and reduce operational costs.

This guide aims to equip you with the knowledge necessary to evaluate and select the optimal flow transmitter for your needs. By considering key factors such as measurement principles, compatibility with existing systems, and specific application requirements, you will be better positioned to make strategic decisions that contribute to the success of your operations.

Understanding Flow Transmitters: Types and Applications

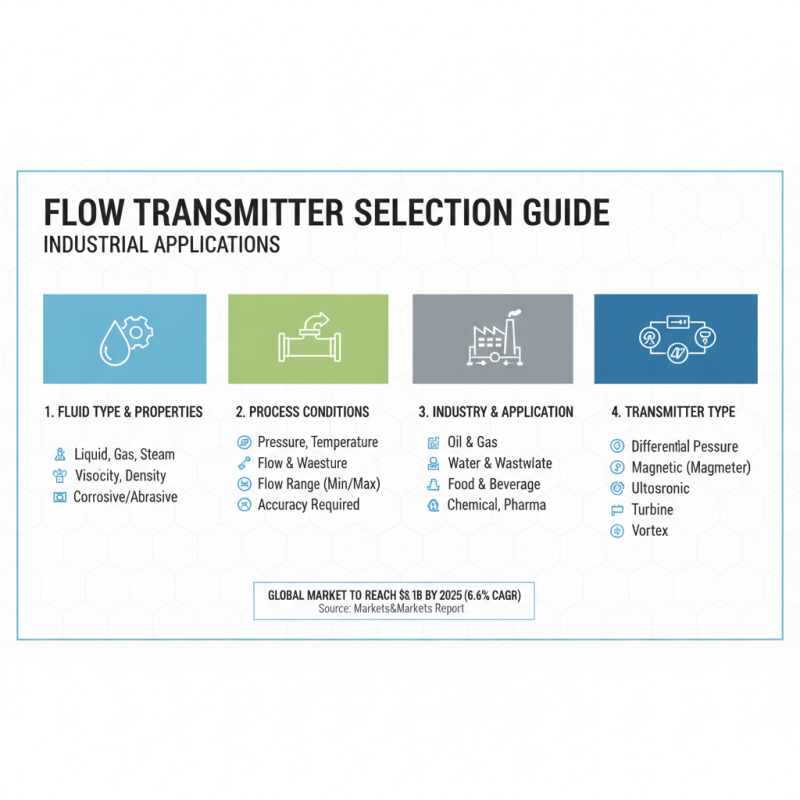

Flow transmitters are essential instruments in various industries, used to measure the flow rate of liquids, gases, and steam. Understanding the different types and applications of flow transmitters is crucial for selecting the right one for your specific needs.

Common types include electromagnetic, ultrasonic, mass flow, and differential pressure transmitters, each uniquely suited to particular applications. For instance, electromagnetic flow meters are ideal for conductive liquids, while ultrasonic flow meters are effective for non-invasive flow measurement in large pipes.

When choosing a flow transmitter, consider the specific application requirements, such as the media being measured, operating conditions, and installation constraints. Additionally, it's important to evaluate the transmitter's accuracy and range, as well as its response time, to ensure it meets your operational demands.

Tips: Always assess the environment where the flow transmitter will be installed, including factors like temperature and pressure ranges. This will help determine the most suitable type of transmitter. Furthermore, consider future scalability in terms of measurement capabilities and integration with existing systems for more efficient workflow management. Evaluating vendor support and documentation for installation and maintenance can also enhance the longevity and performance of the chosen instrument.

Key Factors in Selecting a Flow Transmitter for Your Industry

When selecting a flow transmitter for specific industrial applications, it is crucial to consider several key factors that can significantly affect performance and efficiency. According to a report by MarketsandMarkets, the global flow meter market is projected to reach USD 8.1 billion by 2025, growing at a CAGR of 6.6% from 2020. This growth is driven by the increasing need for accurate flow measurement across various industries, including oil and gas, water and wastewater, and food and beverage. Understanding the unique requirements of your industry is vital in choosing the right flow transmitter.

One of the most important criteria to evaluate is the operating conditions such as temperature, pressure, and the type of fluid being measured. For instance, the American Society of Mechanical Engineers (ASME) provides guidelines on the compatibility of flow measurement technologies with various media, emphasizing that not all transmitters are suitable for corrosive or viscous liquids. Additionally, considerations such as installation requirements, maintenance needs, and the need for calibration can affect the operational reliability of the chosen flow transmitter. Failure to account for these factors can lead to inaccurate measurements and increased operational costs, emphasizing the need for thorough evaluation before purchase.

The choice of technology, whether magnetic, ultrasonic, or differential pressure, also plays a critical role in flow measurement accuracy. A report by the International Society of Automation (ISA) indicates that choosing the right technology can lead to improvements in measurement accuracy of up to 2%, which can make a significant difference in large-scale operations. By meticulously assessing these factors, industries can ensure that they select the most suitable flow transmitter for their unique needs and enhance overall process efficiency.

Comparing Accuracy, Range, and Cost in Flow Transmitters

When selecting a flow transmitter, three critical factors come into play: accuracy, range, and cost. Accuracy is paramount, especially in industries where precise measurement is crucial for efficiency and compliance. According to a recent study by the Flow Measurement Engineering Committee, flow transmitters with an accuracy rating of ±0.5% or better are preferred in applications such as chemical processing and water treatment. These high-accuracy transmitters minimize errors, which can translate to significant cost savings and improved operational reliability.

Range is another vital consideration. Flow transmitters must operate effectively over the required flow rates of the application. For instance, reports from the American Society of Mechanical Engineers indicate that a suitable flow transmitter should accommodate a minimum range of 10:1, and for more specialized applications, even a 100:1 range may be necessary. This ensures that the transmitter can handle variations in flow without compromising reliability or requiring frequent recalibration.

Lastly, cost cannot be overlooked. While investing in high-quality transmitters often pays dividends in terms of performance and longevity, budget constraints may necessitate a careful selection process. Industry surveys suggest that the majority of manufacturers aim to achieve a balance between initial investment and operational costs, with a focus on products that offer the best long-term return on investment. By weighing these factors—accuracy, range, and cost—professionals can make informed choices tailored to their specific requirements.

Installation and Maintenance Considerations for Flow Transmitters

When selecting a flow transmitter, it is essential to consider installation and maintenance to ensure optimal performance and longevity. According to a recent industry report from the Flow Measurement Group, nearly 30% of flow meter failures are attributed to improper installation. This highlights the necessity of careful planning before deployment. Proper alignment, appropriate mounting techniques, and adherence to the manufacturer's specifications are critical to minimize error and maintain accuracy over time.

Maintenance is another vital aspect that should never be overlooked. Regular calibration and inspection of flow transmitters can significantly extend their lifecycle and enhance measurement reliability. The International Society of Automation suggests that regular maintenance can improve accuracy by up to 10%, underscoring the importance of routine checks and servicing. Users should develop a scheduled maintenance plan based on the operating environment and flow conditions to ensure the longevity and dependability of their flow measurement systems.

Recognizing and accommodating these factors will help users select the most suitable flow transmitter for their specific needs while ensuring that it operates efficiently over time.

Future Trends in Flow Transmitter Technology for 2025 and Beyond

As we approach 2025, the landscape of flow transmitter technology is on the brink of significant transformation. Emerging trends highlight an increasing integration of smart technologies, enabling better data acquisition and analysis. According to a report by Markets and Markets, the global flow meter market is expected to reach approximately $8.3 billion by 2025, driven by advancements in industrial automation and the Internet of Things (IoT). This convergence of technologies allows flow transmitters to not only measure flow rates more accurately but also to provide real-time data that can be used for predictive maintenance and efficiency optimization.

In addition to IoT integration, there's a movement towards the adoption of non-invasive measurement techniques. As industries aim to improve process efficiency without disrupting operations, the demand for ultrasonic and electromagnetic flow meters is on the rise. A recent study from Research and Markets highlights that the non-contact flow measurement segment is projected to grow significantly, owing to its ability to provide accurate measurements without affecting the fluid's flow or quality. This trend signifies a shift in how industries will evaluate and choose flow transmitters, placing greater emphasis on technological innovation and operational flexibility. As businesses continue to embrace digital transformation, understanding these evolving trends will be crucial in selecting the right flow transmitter for their future needs.

Related Posts

-

Understanding the Benefits of Turbine Meters in Modern Industry Applications

-

How to Select the Best Turbine Meter for Your Industrial Needs

-

Unlocking Industrial Efficiency: How Advanced Flow Transmitters Improve Process Control

-

Understanding Common Challenges with Magnetic Flow Meters for Global Buyers

-

Innovative Alternatives to Inline Flow Meter Solutions for Enhanced Measurement Accuracy

-

How to Choose the Right Mag Meter for Your Industrial Needs